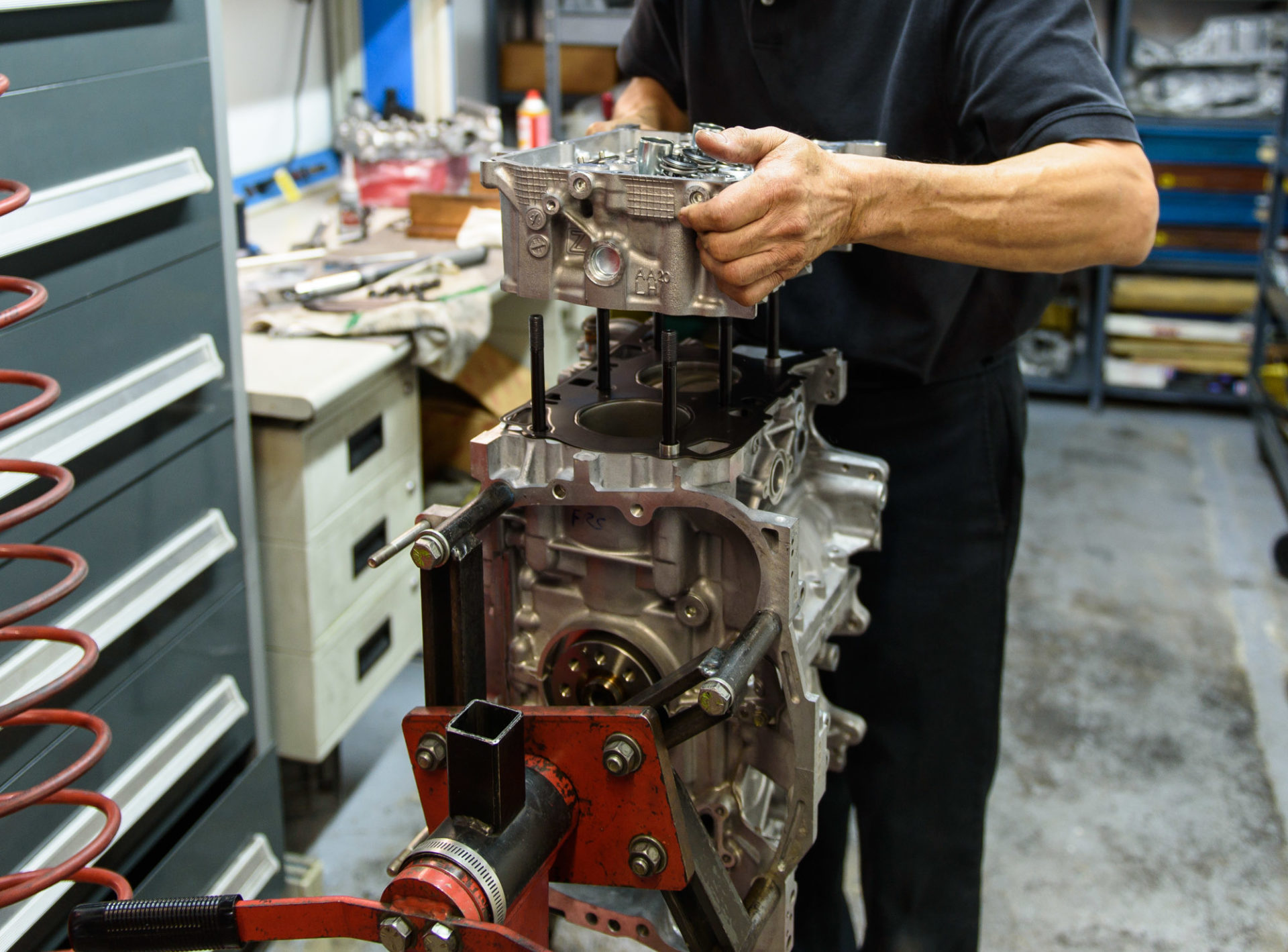

So when we last left off, we were putting together some awesome parts for Michele’s engine and were about to embark on assembling it. In the interest of long-term durability, we added a few tricks to our build over the last one we did for the Stay Crushing car.

Read Part One!

It had inhaled some water somehow and had a bent rod, but we could not find any other significant damage. The engine had been making a knocking noise when it was pulled, and we found that the piston skirt was making light contact with the main bearing buttress at the bottom of the bore.

There was no major damage to the block/engine case, only a light mark. The main bearing bores were straight and within spec, and the cylinder bores were easily within STD bore so we did not have to go to oversize pistons.

After honing the bores, we WPC treated for further wear and friction reduction.

The blued look is the OEM induction hardening of the journals.

The lustrous silver color is the result of the WPC treatment. WPC treated parts have a silky smoothness to them that is readily apparent to the touch.

4 comments

Man, the FA is just not a power motor.

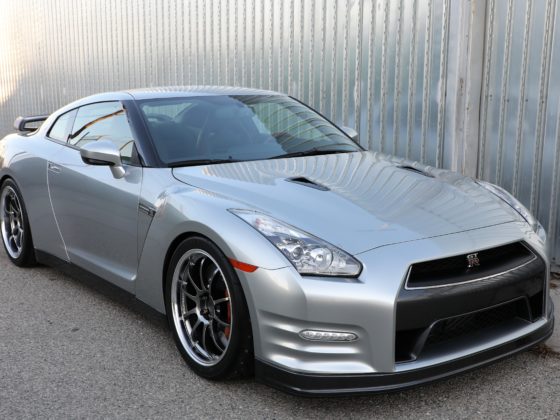

Not the Subaru, but just wanted to drop a line congratulating Michele on her GT-1 podium at the runoffs.

I’m curious why the pistons were coated after wpc treatment. Wouldn’t the tiny dimples caused by wpc be smoothed out or removed by the coating building up? Was wpc just for strength benefits? I’m also confused because I thought I’d read wpc treatment could be done to coated surfaces. Did they mean something harder like chrome?

Thanks in advance for any reply

I was using the WPC for ring groove freeness and longevity and to reduce the galling of the piston up there. WPC can be done to stuff like nitriding and hard chrome but it will remove organic coatings.