Project Lexus SC300 Road Racer: Part 8 – Planning for Performance

So far in the epic rewiring saga of Project SC300 we’ve managed to write thousands and thousands of words, and we don’t even have any wires pulled or harnesses assembled. It just goes to show how much work and planning goes into doing wiring right. While there is still a lot of fabrication to be done and little odds and ends to take care of, it’s time to talk about planning a wiring job. Get your reading glasses ready- this article is going to get wordy.

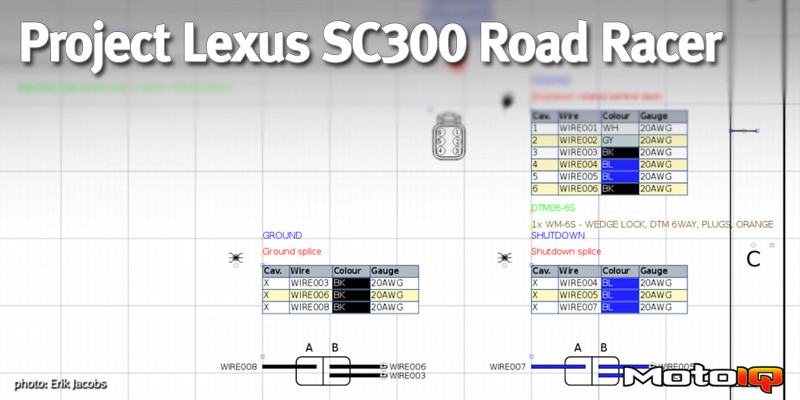

We didn’t just start randomly cutting panels and laying wire, figuring it out as we went along. In Part 4 we decided on a number of electronic components. Throughout the last few segments we have mentioned wires and currents and different considerations for circuits, but how did we get there? Well, it all starts with your plan.

Here’s our friend the Racepak Smartwire.

Here’s our friend the Racepak Smartwire. The Smartwire will be distributing power to almost all of our major systems. There are a few circuits that we did not remove from the existing Haltech plug-and-play harness. However, the Smartwire is generally the heart of our wiring system. Well, maybe it's the lungs. We already said the XS Power battery is the heart. Okay well, it's a really mission critical system.

We chose this system because it offers a good number of inputs and outputs, has prewired switch options, and has an attractive cost. But how did we decide what to do with all of those inputs and outputs? It all started with a wishlist.

Here’s Ed Senf again. The quick recap on him: decades of experience planning, designing and installing motorsport electronics systems, tuning and calibration, championships in World Challenge, Rolex/Tudor/Continental, and all that. He knows a thing or two when it comes to wiring.

Here’s Ed Senf again. The quick recap on him: decades of experience planning, designing and installing motorsport electronics systems, tuning and calibration, championships in World Challenge, Rolex/Tudor/Continental, and all that. He knows a thing or two when it comes to wiring.Ed and I have had a lot of conversations about what is going into Project SC300, and something he always says comes to mind, “the journey is not always about the destination.”

My wishlist was a little silly. I wanted a race car that could be street legal and “all weather”. That meant:

- It needed fully functional lights: both high- and low beams, brake and tail lights, reverse lamps, blinkers and hazards.

- It needed a horn- what race car doesn’t?

- It needed to retain the factory powered in/out up/down steering column.

- It needed both a speedometer and a tachometer- the car actually didn’t have either of those working previously.

- It needed functional wipers, but we settled on one speed (high).

- It needed a “cat” to pass emissions so that it could be registered for the street in Georgia.

Do I expect to drive a caged race car on the street often? No. But then again, the alignment shop is not far from my house and it sure is easier to drive there than to go through the rigamarole of loading it on the trailer!

Do I expect to be doing any racing or driving at night that would require lights? No, not any time soon. But why shouldn’t the headlights and blinkers work? Many racing organizations and track day groups require functional tail lamps and a couple of extra things that couldn’t hurt.

Won’t I be the primary driver? Yes. But it’s nice to be able to retain the factory adjustment to be able to accommodate multiple drivers, so the power steering column remains.

Every vehicle needs Hella Supertones. Period.

Racing doesn’t stop because of a little rain, so wipers were a must regardless of whether or not the car was streetable.

Of course the engine running gear needed to be powered. That’s a given.

This wishlist provided for a good baseline for the plan.

This wishlist provided for a good baseline for the plan.Since I’m a bit of a computer nerd, and wanted to keep track of things and make everything easy, I went ahead and made a spreadsheet using Google Docs. This let me share with Ed and others that needed to provide input or insight.