Project 350Z: Buidling a New Engine – Part 2

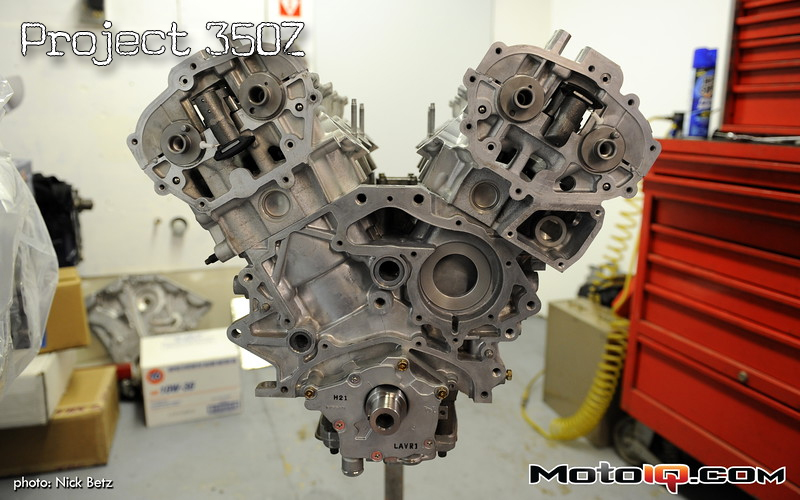

When we last left off on Project 350Z, we were in the process of assembling a group of parts to enhance the durability of our project car. As we stated before we were not looking at building the ultimate naturally aspirated VQ35DE but simply a more durable one that could hold up to a life of track days, drift days and stunt driving practice days. If we could get a little more power out of the engine while we were in there, all the better.

While in there we focused mainly on several early VQ weak points, mainly the weak oil pump, weak connecting rods, poor cooling and bearing issues. Because our Z is an old track beater, (although a well equipped one!) our goal was to accomplish this on a budget with minimal expense on parts and labor. Our goal was also to minimize downtime to return our car to fun use as fast as possible. This is what ruled out a swap to a stronger and much more potent HR engine, exotic headwork and large displacement stroker hybrids.

For this segment, check out how we put the bottom end of our engine together!

One of the parts that was in the process of being shipped when our last segment was being put together was a Fluidampr harmonic balancer and front pulley. We like to use this part on engines that will see a lot of continuous high rpm hard use. What makes the Fluidampr unique is that it uses an inertia ring that is suspended in a viscous silicone fluid. The damper is tuned by the mass of the inertia ring and to a degree by the viscosity of the fluid. What we like is that the damper is both vibration frequency and amplitude dependent since the inertial ring isn’t constrained within the housing. We have found these dampers to work exceedingly well and have had good engine life while using them. Fluidampr claims that there dampers can also free up power lost to vibration and although this may be true on some engine combinations we have not been able to verify this yet on our dyno. We can tell you that vibrations are obviously reduced on any of the engines we have tried them on.

One of the parts that was in the process of being shipped when our last segment was being put together was a Fluidampr harmonic balancer and front pulley. We like to use this part on engines that will see a lot of continuous high rpm hard use. What makes the Fluidampr unique is that it uses an inertia ring that is suspended in a viscous silicone fluid. The damper is tuned by the mass of the inertia ring and to a degree by the viscosity of the fluid. What we like is that the damper is both vibration frequency and amplitude dependent since the inertial ring isn’t constrained within the housing. We have found these dampers to work exceedingly well and have had good engine life while using them. Fluidampr claims that there dampers can also free up power lost to vibration and although this may be true on some engine combinations we have not been able to verify this yet on our dyno. We can tell you that vibrations are obviously reduced on any of the engines we have tried them on. Perhaps the biggest weak point on the early VQ35DE engines is the oil pump. The oil pump gears are fragile and will break during extended use of much more than 7000 rpm. We cured this issue by replacing the gears with the later parts from a rev up version of the VQ. The rev up gears are made of stronger material and are safe up to 7700 rpm. To further increase their fatigue strength we had them WPC treated and had the oil pressure relief valve WPC treated as well as we have had a few Nissan oil pumps fail when this valve has stuck.

Perhaps the biggest weak point on the early VQ35DE engines is the oil pump. The oil pump gears are fragile and will break during extended use of much more than 7000 rpm. We cured this issue by replacing the gears with the later parts from a rev up version of the VQ. The rev up gears are made of stronger material and are safe up to 7700 rpm. To further increase their fatigue strength we had them WPC treated and had the oil pressure relief valve WPC treated as well as we have had a few Nissan oil pumps fail when this valve has stuck. After carefully deburring the oil relief port to reduce the chances of the valve hanging up in that area, we reinstalled it.

After carefully deburring the oil relief port to reduce the chances of the valve hanging up in that area, we reinstalled it. Oil was applied to the inner pump rotor.

Oil was applied to the inner pump rotor.