An Inside Look at mountune's GRC Ford Duratec Engine!

The current engines used in today's GRC Rallycross racers are some of the highest stressed production based engines in all of Motorsports. Only Import Drag Racing engines see more stress and perhaps no production based race engines not even Time Attack engines are stressed for as long a period of time as Rallycross powerplants.

Breathing through a 45mm restrictor that limits power to “around” 550 hp, the mountune Ford Duratec puts out 625 lb/ft of torque. Because of the restrictor, the Garrett Turbo pumps in 45 plus psi absolute of boost to make that power, generating an amazing 3200 psi of cylinder pressure. To put this in perspective, this is more cylinder pressure than the Audi LMP1 Diesel!

To adapt a production based engine to survive in this rigorous environment requires some interesting engineering. Also interesting are some of the engine's peripheral controls meant to provide the instantaneous throttle response needed from a modern AWD racer that must excel on both tarmac and dirt.

Let's take a look inside mountune's Marvelous Monster Ford Duratec engine and see what makes it tick or at least stay alive!

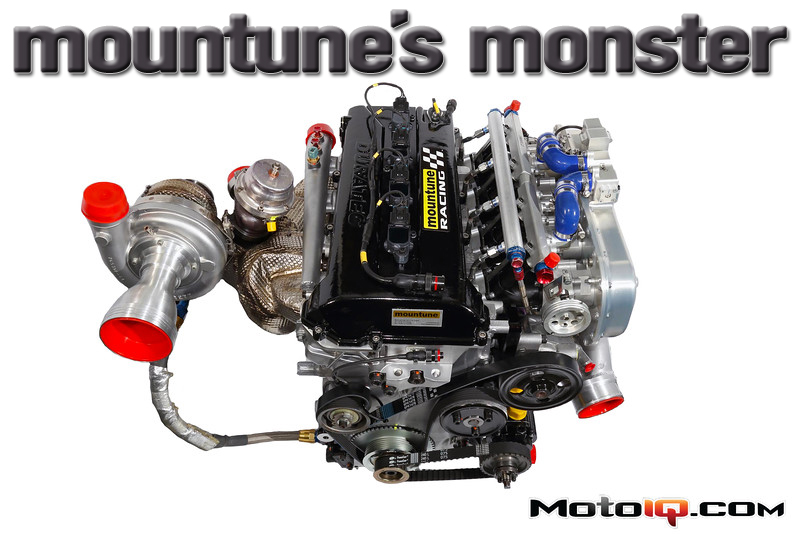

The first thing you notice about mountune's engine is that it's longitudinally mounted. The stock Fiesta is not AWD but to convert it, the engines must be switched to a north/south configuration. There's a lot of external plumbing on the engine and most of that is related to boost control and anti lag hardware. The back part of the block is machined to allow the transmission to be mounted as close to the engine as possible and a few production based bosses are removed to save weight.

The first thing you notice about mountune's engine is that it's longitudinally mounted. The stock Fiesta is not AWD but to convert it, the engines must be switched to a north/south configuration. There's a lot of external plumbing on the engine and most of that is related to boost control and anti lag hardware. The back part of the block is machined to allow the transmission to be mounted as close to the engine as possible and a few production based bosses are removed to save weight.The original development of the Ford 2 liter Duratec engine was done by Olsberg MSE or OMSE. OMSE has successfully campaigned the engine in Rallycrosss and a more restricted version of the powerplant in WRC Rally for several years. Ultimately, the engine had long term durability issues and not the greatest race reliability.

mountune's involvement with OMSE began when mountune founder David Mountain met OSME bossman Andreas Eriksson at the 2009 Pikes Peak hill climb and struck up a deal to aid in the engine's development. mountune started making some changes to the engine in the 2010 season and assumed control of engine preparation and development in 2011.

Since then mountune has made revisions to nearly very part of the motor to improve durability and performance including the block, crank, rods, pistons, head sealing, turbo, intake system, sump and ECU.

mountune's engine is based on the Mazda derived Ford MZR Duratec which is becoming the basis of many race engines from LMP1 protoype endurance racers, to WRC rally cars to BTCC Touring cars and open wheel stuff like the new Formula Ford and Super 2000. In mountune's variant, the block is the production Duratec while the head is a bespoke design by OMSE. While the engine developed by OMSE was fast mountune made many changes to make it fast and reliable.

mountune's engine is based on the Mazda derived Ford MZR Duratec which is becoming the basis of many race engines from LMP1 protoype endurance racers, to WRC rally cars to BTCC Touring cars and open wheel stuff like the new Formula Ford and Super 2000. In mountune's variant, the block is the production Duratec while the head is a bespoke design by OMSE. While the engine developed by OMSE was fast mountune made many changes to make it fast and reliable.One of the biggest changes that you can't see was in the engine control department with mountune going from what was basically a reprogrammed OEM SAAB ECU to a Motorpsorts Cosworth Pectel SQ6 unit. One of the most important features of the Pectel unit that greatly impacted reliability was advanced knock detection and suppression. Although knock detection on tarmac is a pretty understood subject nowadays, on dirt, the vibrations from rocks hitting the chassis makes it much more difficult. A lot of the secret stuff is the ability to resolve actual knock from rock impacts.

The Pectel also afforded higher resolution of the fuel and spark maps, sophisticated launch control and improved boost control strategies. The engine also features a dry sump oiling system and other features we will talk about later.

mountune revised the block prep compared to the original OSME spec. The engine's block starts as a production 1999cc Duratec piece with an 87.5mm bore. mountune pushes out the stock iron cylinder liners and replaces them with stronger nikasil plated steel pieces from F1 supplier Capricorn with a final bore of 88mm. With an 84mm stroke (up from the stock 83.1mm), the final displacement is 2044cc.

The original OSME block used gas filled o-rings for head sealing which proved to be problematic as there was not enough bore spacing to install them correctly, hence they were installed into a step in the bore where they were fully exposed to combustion pressure and the combustion flame front. This led to erosion of the o-rings causing them to fail early.

mountune solved the problem by going to a 5-layer MLS gasket designed and produced by Elring Klinger. The gasket consists of 5 layers of elastomer coasted spring steel that is deeply embossed with a stopper layer. The gasket not only seals better but is also much more forgiving to slight variations in machining. Converting from the o-rings to the MLS gasket has vastly improved the engine's reliablity. All of the head fasteners are replaced with 10 oversized ARP studs for improved torque and clamping of the head gasket.

The production Duratec block has really deep skirts which extend past the main caps. Deep skirted blocks are very stiff and mountune exploits this with a special oil pan which we will see later.

Even with all the prep, the rallycross engine has a relatively short service life due to to the high boost pressures, combustion pressure and the rough operating conditions of rallycross. The engines are rebuilt every 3 to 4 events even though the total mileage for a rallycross weekend is only 25-50 miles of running.