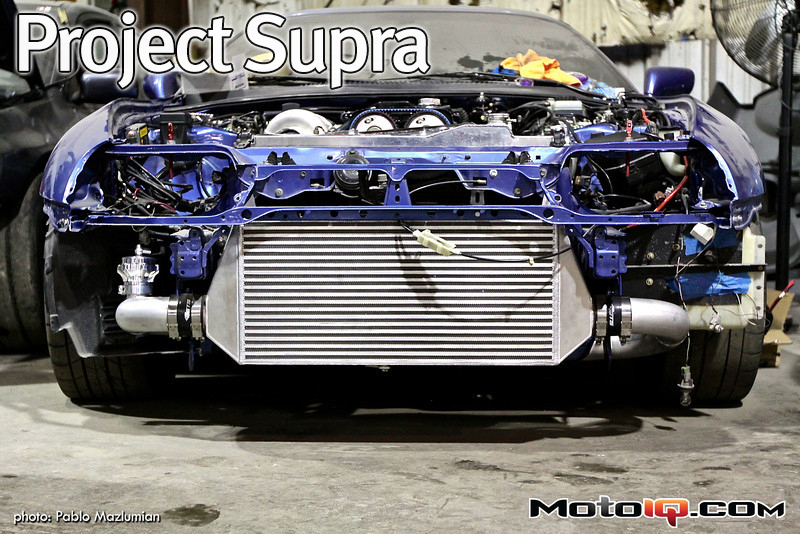

Project Supra gets an ETS intercooler upgrade, which should provide the best of both worlds in flow and cooling efficiency.

Project Supra MKIV Part 7: Intercooling

More than just “bigger is badder”

We know this project is taking a while—trust us, we want this car finished before any of you do. But it’s the extra time (and money) and incidentals that sometimes make projects drag out.

That said, as far as we can tell, we’ve got everything needed to proceed, from the fuel system—which we’ll talk about in an upcoming part—to the new engine management system, which will also be unveiled shortly. In the meantime, it was very important to select a very good intercooler for our application.

Until now, the Supra’s boost was chillin’ through a 3.5-in thick, 28-in long Spearco bar-and-plate core, which worked fine. The temps would stay between 20-25F over ambient at the back of the intake manifold, even at the daily-driven 650 whp. Going by our numbers, we were probably fairly close to maxing out what an intercooler could do for us in terms of efficiency—in other words, the charge air probably wasn’t going to get much cooler with any other intercooler.

Still, we wanted to see if we could get the same—or even slightly better—efficiency, but with significantly improved airflow. Simply going bigger wasn’t the answer, because not only could we introduce more lag, but the efficiency (especially at the rear of the core) and the flow itself could be compromised if we didn’t pick the right design. And that’s all just in the core—we’re not even talking end tank design yet. That said, an eBay knock-off from China wasn’t going to cut it today.

Thankfully, we found a firm that builds its intercoolers in-house, taking all of the above into account, and then some! Enter Extreme Turbo System (ETS), from which we ordered a 4-in intercooler kit.

The ETS intercooler core for the Supra measures 24x12x4-in (30x12x4-in including end tanks), and has a flow rating of 1272 CFM with 81% efficiency at 850 horsepower. This is perfect for our application, and yet it’s the narrowest core ETS offers, which will keep ambient pressure drop to our factory cooling components to a minimum. The firm also provides optional anodized colors of Black, Gold, Red or Blue.

ETS intercoolers can be found in high-powered Import, domestic and even European cars, and it should be of no surprise that they’re all bar-and-plate design (as opposed to the O.E.-popular and cheaper tube-and-fin units). But even more than just bar-and-plate designs, ETS spends a lot of R&D maximizing both ambient and charged airflows through the intercooler while not sacrificing the desired heat exchange (because if air goes through the core too quickly—whether it’s the outside ambient air or the inside charged air—it doesn’t get cooled enough).

According to ETS, it’s all in the fin packs. Says ETS’ Michael Roark, “The reason our cores work so well is our fins are a ¼-in tall, versus ½-in like a lot of our competitors. The height of the fins is crucial. By having a smaller fin pack we get more heat-transfer plates. On a 12-in core, it’s usually 4-6 more charge rows. Each charge row has a heat transfer plate on each side, which is where actual heat transfer takes place.”

Roark adds, “So, when we have six extra charge rows, this results in twelve extra heat-transfer plates. Having these additional plates is especially important in cars that have limited surface area to work with, or a core that is not fully exposed. It’s how we get better heat transfer than our competitors.”

He continues, “since we have more heat transfer plates, we can loosen up the internal fin pack for more flow (less back pressure), but we still maintain optimal efficiency due to more charge rows (or fins) and more heat-transfer plates. Both fin packs are offset and staggered, which allows for good air flow, and forces the air to split multiple times (for multiple fin contact), versus straight-through internal fins like eBay cores, which have minimal contact with the outside of the fin, similar to a tunnel.”

“We also changed our fin design from a “/” to a “TT” design, which gives us great fin-to-heat-transfer-plate contact,” says Roark. “This results in better heat transfer, which takes place right at the tip of the fin pack.”

This is what the staggered and offset fin packs looks like, as described above. ETS reports this improves airflow and forces air to split multiple times for multiple fin contact, as opposed to air flowing straight through like in a cheap eBay core, which will provide less cooling.

This is what the staggered and offset fin packs looks like, as described above. ETS reports this improves airflow and forces air to split multiple times for multiple fin contact, as opposed to air flowing straight through like in a cheap eBay core, which will provide less cooling.ETS reports that, due to the staggered and offset design, ETS’ external fin pack also provides better airflow to the radiator and other cooling components that sit behind the intercooler, as opposed to when the fins are simply louvered.