|

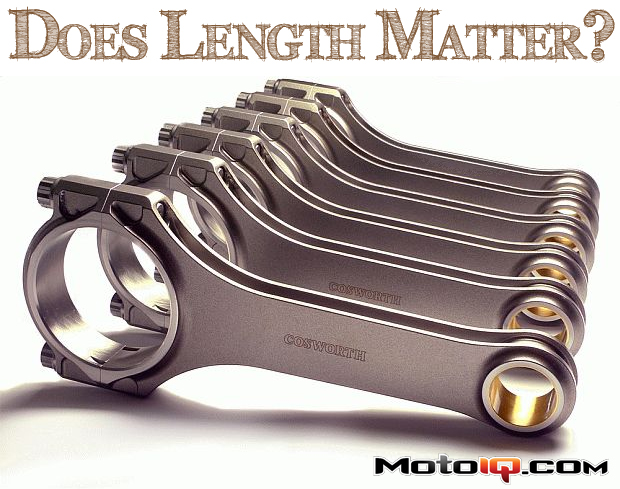

Does Length Matter?

by Khiem Dinh

Khiem Dinh is an engineer for Honeywell Turbo Technologies at the time of this writing. All statements and opinions expressed by Khiem Dinh are solely those of Khiem Dinh and not reflective of Honeywell Turbo Technologies.

Someone recently asked, “Why a longer rod?” Someone else answered, “Longer dwell time.” I never really thought about it before, so I thought I’d look into it. Using some basic math, we can prove that a longer rod does indeed create a longer dwell time around top dead center.

|

| Here’s a diagram showing the geometry between the crank, connecting rod, and piston. The math only works out assuming the piston pin location is not offset. So using some basic trig, we can calculate piston position (S =A+B in this diagram) versus crank angle. |

|

| This graph shows piston position (normalized so that 0mm is BDC) vs. crank angle for 100mm and 300mm long connecting rods on an engine with an 86mm stroke. Yeah, you would never use a 300mm long conrod, but I wanted to make it easier to show the difference. |

As you can see in the diagram, the piston with the longer conrod spends more time around top dead center (0 degree crank angle) due to a slower acceleration rate towards and away from TDC. A longer dwell time around top dead center makes better use of the combustion pressure and turning the pressure into torque; a rule of thumb is that you want peak combustion pressure around 15-17 degrees after TDC. Furthermore, the combusiton pressures are higher while the crank angle is lower resulting in less side loading of the piston into the bore. Less side loading results in less friction between the piston and bore freeing up power and reducing wear. The reduced piston acceleration also improves piston ring life as the lower acceleration equals less force on the rings (remember F=ma?).

|

| The Yamaha YZF R1 is a typical modern sports bike that revs to 12,000 rpm. Its engine has a stroke to rod length ratio of 2.12:1 which is suitable for high rpm use. This can be compared to a Nissan SR20DE engine which revs to 7700 RPM with a rod to stroke length ratio of 1.58:1 |

|

| The R1 engine has a pretty tall deck height compared to the general compactness of the crankcase. In the case of the bike, the chassis is designed around the engine. With a 110.5mm rod and a 52mm stroke, the engine is tall for its displacement compared to a car engine. |

|

| We think automotive engine designers compromise rod length to try to fit engines under low hood lines of modern cars. This is one of the reasons why the SR20DE ended up with a pretty poor rod ratio for a performance motor. |

4 comments

I know one F1 engine manufacturer with a ratio of 3.2 and the connecting rod weighs 2 gram less than a clearly shorter connecting rod of a competitor.

The current 1.6L turbo era? I’m curious if one did better fatigue life calculations than the other, allowing them to go lighter.

Regarding the current turbo era, one manufacturer has a ratio of 2.25 for their 1.6L turbo engine.

No, both are from the V8 era? If you are interested in getting more information, where can I contact you? I don’t want to post such information online.