The other day I was learning the ins and out of the engine dynos here at Cosworth. Upstairs on top of the dynos are a 2200 gallon water tank, vents, fans, chillers, boilers, transducers, sensors, 9000 valves and solenoids, and miles of copper, iron, and stainless piping and tubing all on top of 14″ thick cement floors. The dyno cells have 8″ thick solid walls to keep the noise and explosions within the room. Anyhow all of the stuff upstairs is to supply water to the water brakes and conditioned air so the engines can ingest air of exact temperature, humidity, and barometric pressure that we designate for that test. It's pretty damn complex, but required so that each engine test is EXACT. As an example, when we were building Champ Car engines, each engine had to be within 1% power output or it was failed because it was a spec series. All of the Cosworth XFE 2.65L V8s cranked out 750bhp and all had to be within +/-3.75bhp of 750bhp or it was failed.

On top of the dynos are also treasures from the past and current. It's kind of a like a storage area for past engine programs and just general stuff. I could spend days up there just looking through stuff and thinking, “Why did the XD use a billet TPS sensor that cost $900 each and have 2 of them?”, “Why did the XF's 9th throttle use a $7200 motor?”, or “Why does a manifold pressure transducer [MAP sensor to us tuner guys] cost $1040 each and why are there 3 of them on the plenum?!?” High level motorsports is a bit beyond me, but I guess it is components like these that keep an engine reliable at 16,000rpm for 500 miles (XF) or 12,500rpm for 1500 miles (XFE).

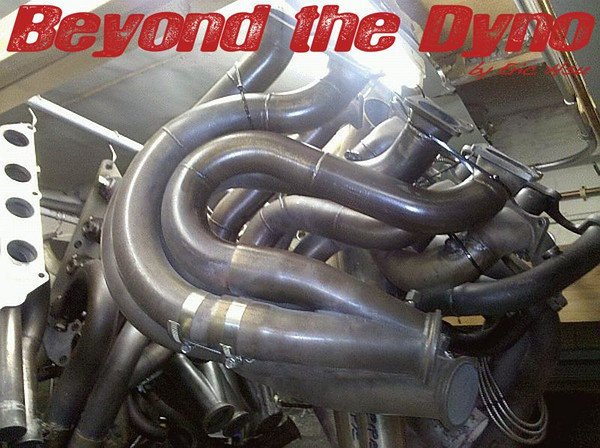

Anyhow, there were also a pretty big section of headers and exhausts used on the various engines throughout the years. I looked at the collection of 321 stainless and Inconel and thought to myself how much the collection must have all cost brand new. I estimated maybe $50-75k? Check out some of the headers below.

Some headers

And more headers…

And even more headers…

These are some Champ Car/CART headers. I really like the look of a header with huge sweeping primaries with near identical bends. It just looks ultra freaking cool.

I'm not sure what these belong to, but I'm guessing something having to do with NASCAR with the outlet looking like that.

Another NASCAR exhaust? This thing is a giant exhaust that was all hand fabricated.

And there you have a quick peek at some of the dyno headers in storage here at Cosworth in Torrance. Throughout the building there are more headers here and there, but this was the largest grouping of headers throughout the building. All pictures were taken with my new Motorola Droid. I'm finding the 5MP camera isn't too bad with the LED flash.

There is some pretty cool stuff around here. More later…