|

Turbo Tech: Generating Compressor and Turbine Maps

By Khiem Dinh

Khiem Dinh is an engineer for Honeywell Turbo Technologies at the time of this writing. All statements and opinions expressed by Khiem Dinh are solely those of Khiem Dinh and not reflective of Honeywell Turbo Technologies.

Compressor and turbine maps are the spec sheets for a turbocharger. They characterize the performance of a turbocharger allowing engineers to properly choose the correct combination of wheels and housings for their particular application. Compressor and turbine maps for a turbocharger are the equivalent of a dyno sheet for an engine; the maps and dyno sheet provide performance information over a wide range of operating conditions. In the same way engines need specialized equipment to get a dyno sheet, turbochargers also need specialized equipment to generate compressor and turbine maps.

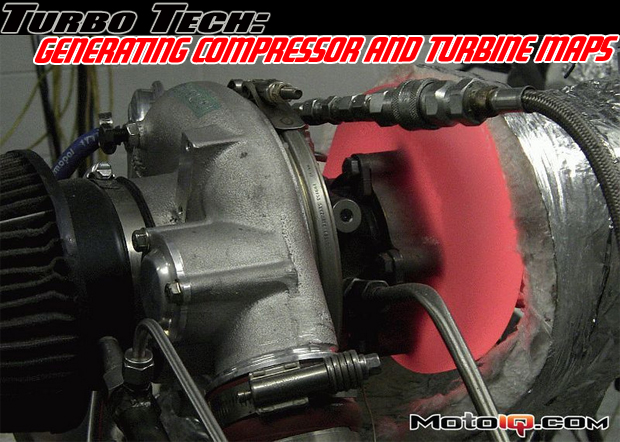

Typically, compressor and turbine maps for turbochargers are generated by running a turbo on a properly instrumented gas stand in a test cell. A gas stand typically burns natural gas to drive the turbocharger. The test cell, with the gas stand inside it, provides a controlled and consistent environment for repeatable testing. It would be possible to make a compressor dyno that would only test the compressor side relatively easily but the turbine side can be much more complicated. Also, the turbine map changes drastically depending on the compressor wheel, bearing system, and turbine housing used for testing. The compressor housing itself can also have a minor affect on the turbine map. Therefore, it’s the match of a compressor and turbine that determines a turbocharger’s performance, so it’s convenient and logical to test them together in the form of a turbocharger.

Generating the compressor and turbine maps requires accurate and precise measurements of mass flow rates, temperatures, pressures and turbocharger shaft speed. The maps are generally created by running the turbocharger at a constant speed and varying the pressure ratio on the compressor side. This can be done by restricting the flow on the compressor outlet. Every speed line on a compressor map for a turbocharger has a matching line on the turbine map.

|

| Here is a compressor map from Garrett. Notice each of the individual speed lines on the map. On a Garrett map, the left most point of the line is determined by compressor surge and the right most point by 60% efficiency. Each speed line is created by taking data at multiple points and connecting the dots. The gas stand must maintain the turbocharger at each point for a certain amount of dwell time in order for all the readings to stabilize. If the gas stand were to just sweep across each speed line, the readings would not accurately reflect the actual efficiency due to the time lag for components to reach stabilized temperatures. It’s like boiling water on the stove; it takes the water a while to reach boiling temperature. |

|

|

| Here is a compressor map from Borg Warner. The Borg Warner map is a little different in that they plot out the speed lines until the pressure ratio nearly goes down to 1.0. |

Plotting compressor speed lines versus pressure ratio and mass flow rate is relatively easy as measuring pressure and flow rates is simple to do with a high level of precision and accuracy. For a compressor, it’s even relatively easy to calculate efficiency. The basic definition of efficiency is how much you get out of something versus what you put in. I seem to only have about a 99% sock washing efficiency as I seem to only get back 99 socks out of every 100 I wash. For a compressor, efficiency is defined as compressor power out divided by power put into the compressor; if you recall, I covered this in Compressor Efficiency and More. In short, to calculate compressor efficiency, you only need to know temperatures and pressures if you make an assumption of a constant specific heat value; this is a reasonable assumption when the temperature range is only a couple hundred degrees Celsius.