|

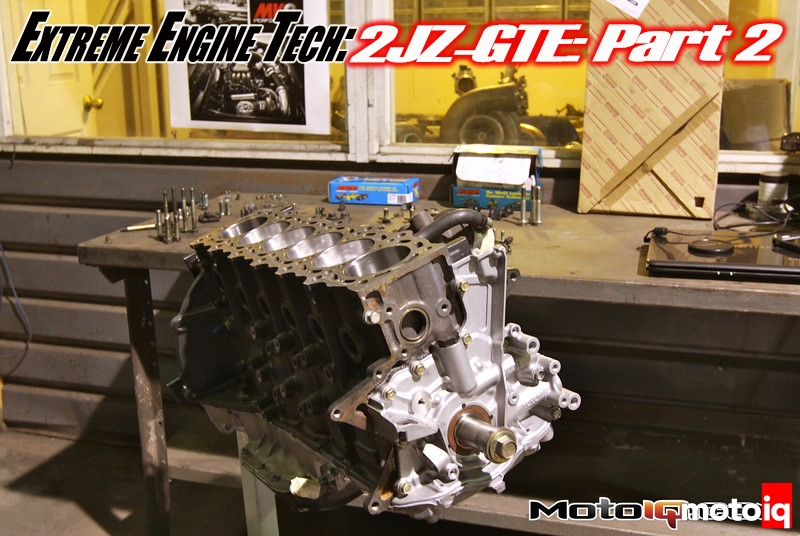

Our engine block still rests on an engine stand at Modified by KC in Kansas City, MO (don't worry, the cylinder taping was removed for picture purposes only). Once we receive our anxiously awaited hand-built parts from Power House Racing and Hypertune, the cylinder head will be completed and married to the block. |

EXTREME ENGINE TECH 2JZ-GTE; Part 2 – Good Vibrations and Better Lubrication

by Pablo Mazlumian

In the first part of our engine build we discussed the engine block internals, including JE asymmetrical pistons, K1 Technologies connecting rods and ARP main studs. Follow the link to catch up on our 2JZ build: Extreme Engine Tech: 2JZ-GTE; Part 1 – More Strength, Less Weight

Modified by KC hasn't been able to put the cylinder head on yet because we're waiting on a couple of hand-built parts, one of them an intake manifold from Hypertune in Australia, and the other an exhaust manifold from Power House Racing. These parts take time to build but should be well worth the wait. We're expecting them any day now.

Once we have the parts in hand, Jeff Gerner from FRP Engineering will finish port-matching the cylinder head to each component, and Brad Noland from Noland Cylinder heads will finish assembling the head with our Ferrea valvetrain and new factory shimless lifters we got from Champion Toyota. At this point, the rest of the process should start flowing a little more quickly.

In the meantime, let me share the details on a couple of important components that we needed to order for the block. Sure, the motor is—in loose terms of the phrase—”bullet proof” with its new internals. But, to be fair, even with proper tuning no engine is bullet proof without the proper lubrication and vibration damping. And, while neither of these subjects had anything to do with our melted piston in Part 1, it doesn't mean we were going to be problem-free several miles down the road had this not happened. In fact, upon disassembly we came to find out that a full-locked engine doomsday was probably just around the corner!

|

When any modification is done to the engine, the natural harmonic frequency and magnitude can change, and bad things can happen if a proper crankshaft damper—a.k.a. “harmonic balancer”—is not installed. With a previously installed aftermarket lightweight crank pulley, it was evident there was enough vibration to cause some damage after just 10k miles. This is a shot of the oil pump gear on our factory oil pump. Notice the nice crack. |

|

A quick peek and the above gear crack didn't look so bad at first. Hey, it was pumping oil fine and who's to say it would have stopped? Problem, however. Pictured here is what the pump housing looks like with the gear removed. Notice the grinding. Sure, this was probably robbing a bit of horsepower, but the worst thing is the gear was most likely ready to seize! Anyone care to guess what happens when oil quits circulating? This was a huge find. |

A proper amount of mass is required to properly dampen crank vibration, so re-installing a lightweight pulley was not an option. Rubber factory dampers are effective, but they're only safe on a stock motor. The problem is, an engine is so dynamic that any changes, like pistons and rods—or even an intake and exhaust, according to Fluidampr—will change the vibration frequency and/or magnitude, and often move these out of the range that a rubber damper can handle.

Our solution was to souce a crank damper from Fluidampr. At around $400, these units are a bargain, especially when compared to the factory, rubber-based units which sell for nearly $300!

|

Needing a high-quality damper, we turned to Fluidampr, which boasts a unique crank damping method that is race proven. Instead of making one generic damper for a variety of cars, Fluidampr designs and tests each of their dampers for the specific make/model and engine application. Fluidampr tests their units in racing environments as well. |