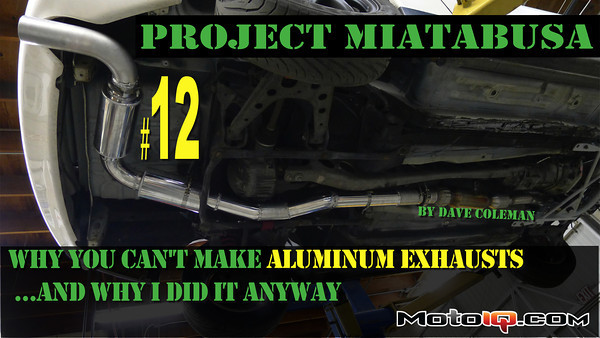

Project Miatabusa part 12: Why You Can't Make Aluminum Exhausts… And Why I Did it Anyway.

by Dave Coleman

From exhaust port to tailpipe, project Miatabusa's exhaust system fabrication has stretched well over a year and has followed a circular evolution from brilliant hack job, to exotic race tech, and back to brilliant hack job. From custom-fabricated race header, to a lightweight aluminum tail section, to scavenged RX-8 silencers and hangers made from an S13 power steering cooler, the exhaust system is as awesomely eclectic as project Miatabusa itself.

I'll get to the header in a second, but let's talk about the aluminum back section first. In theory, there's no reason we couldn't use any old off-the-shelf aftermarket cat-back exhaust for the Miatabusa. Exhaust flow is pretty closely correlated to horsepower, and our power output will be well within norms for Miata exhausts. There's nothing at all off the shelf about the exhaust we just built, though.

The aluminum exhaust adventure began when I was browsing through Vibrant Performance's very tempting collection of fabrication components, and I stumbled onto their 4-pound aluminum race mufflers. Whaaa? I had always written off aluminum as an impossibly soft, temperature sensitive and fatigue-prone material for exhaust use. But if someone is making aluminum mufflers, that must mean someone else is building exhaust systems with them.

The aluminum exhaust adventure began when I was browsing through Vibrant Performance's very tempting collection of fabrication components, and I stumbled onto their 4-pound aluminum race mufflers. Whaaa? I had always written off aluminum as an impossibly soft, temperature sensitive and fatigue-prone material for exhaust use. But if someone is making aluminum mufflers, that must mean someone else is building exhaust systems with them.

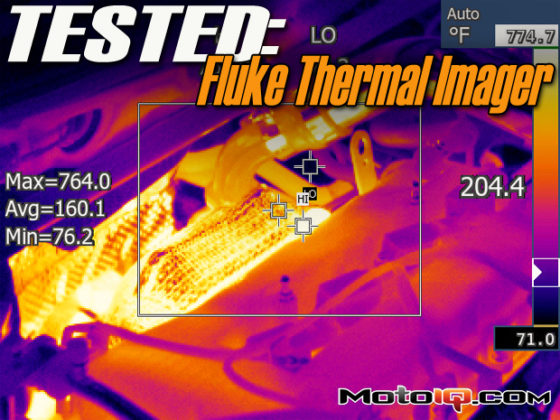

The temptation to use aluminum should be obvious. Steel exhaust systems are really heavy, and an aluminum exhaust has the potential to save dozens of pounds. Burns Stainless has a very thorough, well-reasoned explanation for why they don't do aluminum exhausts. The short version is this: Aluminum's strength falls off dramatically at elevated temperatures. At room temperature, 6061-T6 aluminum actually has a slightly higher yield strength than 304 stainless, but by around 500F, it's about half the strength of stainless.

|

| For Burns Stainless' full dissertation on why they don't build alminum exhausts. That blue line really sums it up though. That's the yield strength of aluminum plunging as temperatures approach those we'll see in an exhaust system. The purple line on the bottom is the yield strength of annealned 6061-0 that you'll find around all your welds. Yikes! |

The heat treat of aluminum is also critical. 6061 is the alloy (basically the only alloy you're likely to find in tubing suitable for exhaust fabrication), and the T6 is the heat treat. Annealed 6061 (called 6061-0) is roughly one quarter the strength of 6061-T6 at room temperature, but at 500 degrees, they're both equally weak. Annealed 6061 is relatively stable vs. temperature, but heat brings the T6 aluminum down to the strength of the annealed material. Another tricky bit is that welding 6061-T6 basically anneals it, so a fabricated exhaust will be as weak as 6061-0 around the welds.

On the other hand, the aluminum tube Vibrant sells (1.5mm wall thickness) weighs roughly half as much as even thin, 18-gauge stainless. That's the kind of temptation I can't pass up.

At first blush, an exhaust shouldn't really need to be that strong. All it does is keep the smelly gas on the inside and the slightly less smelly gas on the outside. How strong does a metal tube have to be for that? Turns out there are a lot of sources of stress on the exhaust that could make hot aluminum's strength issues problematic.

You can't see them, so they're easy to forget, but any fabricated component is full of internal stresses from different parts of the material disagreeing over what shape they should be. A mandrel bent tube, for example, has been stretched and pulled into a bent shape, and welded part will have stresses left over from the expansion and contraction that happens as material around a weld heats and cools. Heat treating the final product is the only way to get rid of these internal stresses, but it still won't change the fact that there are huge temperature swings across the material during operation, with hot sections expanding more than cool sections and fighting each other over how big they should be.

Easier to visualize (and manage) are the stresses the exhaust sees from driving the car. Go around a bumpy corner at 1g and you're effectively hanging the exhaust sideways on its mounts and bouncing it up and down. This can concentrate tremendous stress where the hangers weld to the exhaust, and where the rubber-hung back-section connects to the front section that's inevitably rigidly mounted to the cylinder head. If the rubber hangers are soft enough, and there's no flex joint, it can be like you're holding the front end of the exhaust and swinging it around, concentrating incredible stress on the front flange of the exhaust.

The biggest one, of course, is the huge stress of bottoming the exhaust out on a driveway or trailer. The bottom of this car is already covered with trailer loading scars, and that's on good, old-fashioned mild steel frame rails.

Still, none of this was enough to keep me from trying an aluminum exhaust. Knowing where all these stresses come from means I can design the system to minimize them. I've effectively designed the alumium exhaust to be gently cradled under the car in a way that should keep it from being bottomed out, and designed the hangers and front flange to minimize stress concentrations. I've also limited the aluminum use to the cat-back section where temperatures should be lower. The hotter front half (which is also subject to more cyclic stresses from engine vibration) is all stainless.

I'll get to the aluminum details in a bit, but first, let's back up to the exhaust ports and follow this whole system from front to back:

In the concept stage, we had hoped there would be enough clearance under the engine to retain the stock header and just turn the exhaust 90 degrees once it entered the collector. When we first bolted the Hayabusa engine to the Miata transmission, this simple idea looked doomed. The header was occupying space that would be needed by the subframe.

As you can see in this photo, the Hayabusa header has unconventional pulse primary pairing. With a 1-3-4-2 firing order, you generally want to pair the primaries of cylinders that aren't firing right after each other. This means 1 and 4 should be paired, and 2 and 3 should be paired. Suzuki paired adjacent primaries instead.

This strange pairing is probably the reason the intake trumpets are two different lengths and the fuel and timing maps are cylinder dependent. This pairing means the timing of the exhaust pulses hitting the center two cylinders is different from the outer two, requiring different intake tuning and different maps. Suzuki probably did this to spread out the powerband so the engine's massive power output was easier to put down to one little tire. It also seems to package better inside the aero-sensitive fairing of a bike designed for top speed.

1 comment

Hey,

Do you have any updates on the reliability of this? Thanks!