Making It Stop – Every Time

by Martin Gonzales & Steve Rockwood

Check out the rest of our Project Infiniti G20 Racecar build here!

Loud engines, big horsepower, gratuitous tire smoke, and high cornering speeds are why we love and watch motor sports. Most people, when they watch racing on TV, listen for the engines, stare at the gruesome crashes or marvel at the speeds drivers carry through the corners. However, much like the scrappy player on a basketball team that gets all the rebounds and never scores, brakes just don't get the attention they deserve. It seems that most people only pay attention to brakes when they're glowing red-hot during those late night endurance races, or when they don’t work. Newton's Third Law was 'for every action, there is an equal and opposite reaction,' and as it turns out, Newton was a pretty smart guy. A good braking system on a racecar is as necessary as a good engine.

|

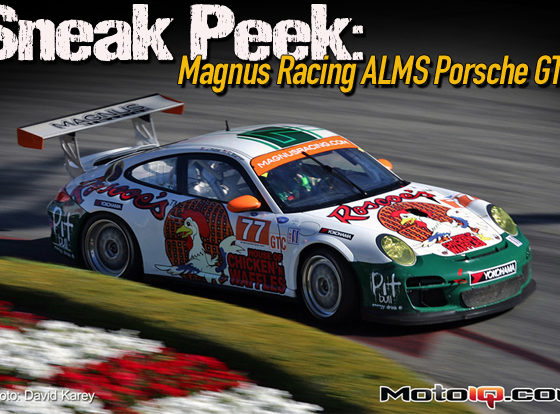

| Unlike an ALMS racecar, our G20 simply does not have the weight or power to justify an extravegant brake set up. |

Only about ten percent of each lap is spent braking, the other 90% is spent, to some extent, on the throttle. What this tells us is that while brakes are important, more effort should be spent on ensuring reliability and fade resistance rather than ultimate stopping power. Those massive manhole covers with 6 piston calipers may look dead sexy, but when you only have 225mm worth of tire and 2400lbs’ worth of vehicle to stop – motivated by only 170-ish-whp – you're not exactly justifying their existence or their premium price tag. Racing is expensive enough!

|

| Project G20 getting some race miles on her with NASA's SE-R Cup. |

The goal of our braking system is to be simple, and have as little wallet-pulverizing potential as possible. While many feel that larger brakes are necessary, we were willing to attempt to use the stock brake set-up with upgraded pads and lines to see how well it works. We wanted to use OEM parts in as many places as possible because of reliability and ease of replacement. While multi-piston calipers and larger rotors are legal for the series, we wanted something, that if necessary, we could just run to the local parts store to pick up in an emergency. In addition, while most aftermarket calipers work great, they often need more attention to maintenance than their OEM cousins. Mom doesn’t notice something wrong with her brakes until they make horrible noises, or stop working altogether, so OEM engineers are paid to look out for Mom. We’re happy to report that in our car's current state of development, the stock system has performed well, and has withstood many race laps without noticeable fade or abnormal wear.