Engine Tech, Building the Nissan VG30DETT part 2

By Mike Kojima

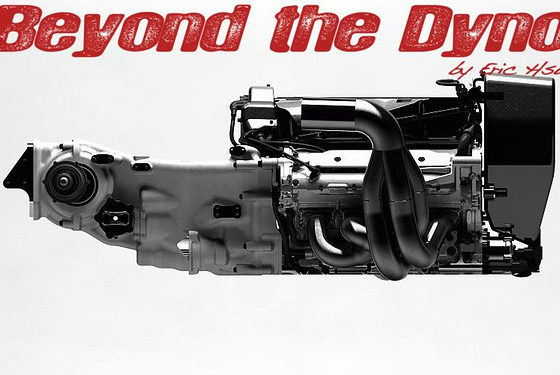

In the last installment of our build, we delved into building the bottom end of our VG30DETT engine for the goal of reliably achieving 550 plus horsepower. In this segment we will look into what was done to our top end including the cylinder heads to support this power level.

See part one about the bottom end here!

The Heads

Our VG30DETT heads and lower intake manifold were ported and polished by JWT to increase flow without losing velocity. JWT stressed keeping the runner volume as low as possible while removing obvious obstructions in the ports flow path. The valve seats were matched to the port walls and combustion chamber to remove the slight mismatch that the factory does not bother to correct. The ports were also straightened for a less obstructed run into the combustion chambers with an emphasis on tumble upon entry into the combustion chambers. This kind of porting helps keep turbo lag to a minimum and does not sacrifice too much bottom end power to gain top end. The old school style of porting where the ports were simply hogged out to be as big as possible often reduced flow velocity to the point of making a car lose much of its bottom end power. The latest style of porting that most good tuners use emphasizes port flow velocity to maintain good low end power as well as peak flow. As a final touch, the combustion chambers were polished to get rid of any potential hot spots that could cause detonation.

|

| Smooth porting on the intake port gives a nice line of sight straight to the combustion chamber. The black coating is Swain Flow Coat which makes the port walls slicker. |

After replacing the valve guides and valves with new genuine Nissan parts, JWT finished the heads with a multi-angle valve job which includes a 30 degree back cut on the valve face for better low lift flow. Multi angle valve jobs work by unshrouding the valve seating surfaces and making a smoother flow path for the incoming air or the outgoing exhaust. These valve jobs commonly consist of a throat cut, a seating cut and a top cut. Stock factory valve jobs usually are just seating cuts. Multi angle valve jobs create a smooth transition from the port to the cylinder as the intake valve opens. The converse effect is also true on the exhaust side of the engine but the flow is improved as the flow proceeds from the combustion chamber to the exhaust port. These type of valve jobs increase the flow the most at low lifts where the valves are first opening or about to close. This is important because valves spend more dwell time opening and closing than the do at maximum lift. A proper valve job can contribute up to 50% of the total flow gain enjoyed by good headwork.

|

| You can see the contouring of the valves and the reduced diameter of the intake valve stem. The contouring is less aggressive on the exhaust valve as it has to deal with a lot of heat on a turbo engine. The white stuff on the exhaust valve is thermal barrier coating and the black stuff on the intake valve is flow coat. |

2 comments

Question, what head gaskets are you using with the 89mm overbore?

It’s been so long ago but I think they were HKS.