Project 200SX – Track Ready?

By Wes Dumalski

It's no secret that driving your car at speed on a road course will bring to light all of the car's weaknesses. After sorting the motor and suspension we decided to take Project 200SX to a few track day events to put the car through its paces. While the car has proven dead reliable we certainly found its shortcomings. The 20-30 minute sessions revealed water temps. that would spike over 200 degrees, oil temps. that would approach 270 degrees, and brakes that fell short…… We knew that if we are going to take this project through the N.A.S.A. H.P.D.E ranks to run Time Trials we would have to make these issues disappear.

First we sorted the water temp. issues. To be honest we were somewhat surprised that we had water temp. issues at all. While the car was not overheating, peaking over 200 degree's is too hot for our liking. We already had a Koyo radiator on the car, and the only thing we could think of to make it more efficient was to fabricate ducting. The logic here is to take all of the air entering the front of the car and force it to go through the radiator.

|

| Here you can see the large gaps around the radiator allowing air to flow around the radiator rather than through it. |

To do this we used some sheet metal stock (think HVAC section of your favorite home improvement store), a bench vice, and some tin snips. We fabricated the top panel first, we removed our hood latch (as we previously had installed hood pins) so that we could use one continuous panel across the top of the radiator that contained no holes. The top panel extends down from the radiator core support and then bends up to meet our Stillen grill. We spent a lot of time test fitting and trimming but the end result is a panel that fits flush on the inside of the grill forcing all entering air through the radiator. We then fabricated the side panels. They took a LOT more time as we wanted them to contour to the bumper core support. It was important that the side panels seal tightly to the radiator itself and then extend to the front facia of the car. Again we wanted ALL incoming air to make it's way through the radiator. After MUCH test fitting and trimming the side panels were riveted to the end of the radiator and then the top panel was riveted to the side panels.

|

| The completed ducting ensures all air flowing in through the front bumper opening and the grill will go through the radiator. These simple panels decreased water temps. by 20 degrees. |

The result? Our temps. before the ducting would reach over 200 degrees half way through a 20 minute track session forcing us to take cool down laps. With no other changes and nearly identical weather conditions our water temps. have yet to get over 183 degrees. Even during full 30 minute sessions with ZERO cool down laps and 90 degree heat! We were amazed with these results from this simple modification. This means you need to run out to your nearest home improvement store and buy some sheet metal!!!!!!!

Our trusty oil temp. gauge also told us that if we valued our motor we needed to get the temps. down. Prolonged exposure to temps. above 260 degrees can lead to bearing failure and is HELL on engine oil so an oil cooler was called in to order. Because there is no off the shelf kit we had to turn to our friends at B.A.T. Inc. to source our parts. First and foremost if you need anything plumbing, especially oil cooler related, related British American Transfer (B.A.T. Inc.) is the first and only place you will need.

|  |

| Our oil temp gauge uses a probe that we put in the oil pan. | The gauge is easy to see while on the track. |

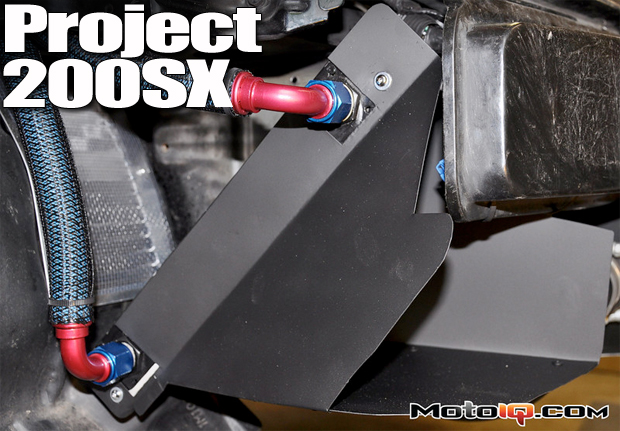

After consulting with Eric we determined that a full size Setrab 19 row oil cooler would do the trick, we coupled that with a Mocal thermostatic sandwich plate adapter and -10 lines. To obtain clean airflow for the cooler we mounted it behind the passenger side fog light opening, this location also provided shorter line runs as the oil filter is also towards the passenger side. We ran the lines up through the engine bay to keep as much of them out of harms way as possible. For lines we used aeroquip push lock hose and fittings, we were impressed with the strength of the hose and its ease of assembly! We used a braided wrap over the lines to offer additional abrasion resistance should something come in contact with the lines.

|

| The Mocal sandwich plate has a 160 degree thermostat to facilitate quicker oil warm up. |

|

| Even with the Mocal adapter in place the oil filter is still easy to access. |