Header Design Part One

By Sarah Forst

A header is one of the first bolt-on modifications most tuners undertake but there are many factors involved in how to choose the best header design for your ride. Let’s get into the detail behind header design and how to choose what will work for your ride! Part 1 of this article will discuss the components of a header and the materials used to manufacture them. Part 2 will go into detail on how a header makes power and what design will produce your desired powerband.

-Sarah

Header

Most stock engines are equipped with a cast iron, log-type exhaust manifold, a design adopted with fitment, cost, and emissions requirements in mind rather than performance. A log manifold simply connects the exhaust ports to the exhaust system. The thick cast iron material retains heat more than thin walled tubular headers, but since catalytic converters must be very hot to work properly, the crude stock exhaust manifold dissipates less heat under cold start conditions, helping to light off the catalytic converter during cold starts. A log manifold is usually smaller than a tuned tubular header and can fit more easily in a cramped engine compartment. However, a true tubular header is the best choice for producing power.

|

| A stock cast iron exhaust manifold is designed for quick cat light off, clearance around the engine and low cost before power production |

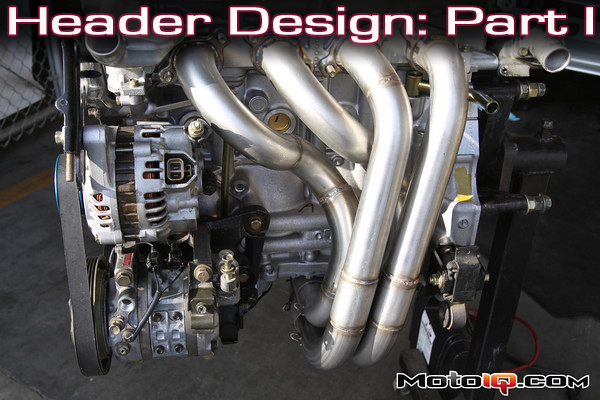

A performance header can produce decent power gains with few disadvantages. A tubular header is an exhaust manifold fabricated from tubular sections of a pipe with longer runners or primary tubes than a typical log style exhaust manifold. The most free-flowing design includes full radius mandrel bends. A header joins each exhaust port to its own primary runner. The runners then come together into a single, larger diameter point known as a collector. The collector leads to the main exhaust pipe and out of the tailpipe.

Headers produce more power for two main reasons. They increase volumetric efficiency and exploit the energy created by the charging exhaust gases during the overlap period at the end of the exhaust stoke and beginning of the intake stroke, when both the intake and exhaust valves are open at the same time. The header’s pipe length and diameter is designed to take advantage of these high-flowing exhaust gases to create a suction that will help scavenge the spent exhaust gases and pull in a fresh air/fuel mixture.

|

| This AEBS header is a unique design as it merges the primary pipes from the cylinders adjacent in the firing order, yet it still makes decent horsepower. |

Pipe design

The primary pipe diameter is a factor of different mechanical traits, such as compression ratio, cam profiles, and desired powerband. It plays an important role when designing the header pipes because it impacts the exhaust gas velocity and volumetric efficiency. Achieving the highest exhaust gas velocity will maintain good throttle response and torque in the low to mid range while producing the lowest possible backpressure and the highest exhaust flow volume, maximizing power in the mid to upper rpm range. Many tuners incorrectly assume that designing a header with large diameter piping in the primaries will produce more power. A larger diameter header pipe will flow more but have low velocity, which is detrimental to the scavenging effect. The exhaust air will cool down and become denser, losing volume, velocity and inertia, making it harder for the engine to push it out of the tailpipe. A smaller diameter header pipe will keep up the exhaust gas velocity but won’t flow much volume. Finding the happy medium of the exhaust flow dynamics is the key to making power.

|

| This Nissan SR20DE header made by ASP features equal length primary tubes and 321 Stainless construction. It makes lots of power |

Primary tube length is also a factor in header design. Pipe length is designed to optimize wave tuning for a desired rpm and the pipes can be sized to move the torque curve in either direction. The primary pipes should all be near equal lengths or within 1-2 inches of each other. Unequal length header pipes tend to vary the cylinders in wave scavenging, which can cause different air/fuel and timing requirements for each cylinder. Some aftermarket headers have variances of 8-10” or more in the pipe lengths, typically not optimal for the best power. The primary pipe entry angle to the collector is also important. Optimally this is 7-10 degrees but is typically around 15 degrees, which will help transition the exhaust gases from the primary pipes into the collector more smoothly.

|

| These DC headers for the 350Z feature 304 stainless construction and merge collectors |

1 comment

You guys make sr20 ve headers