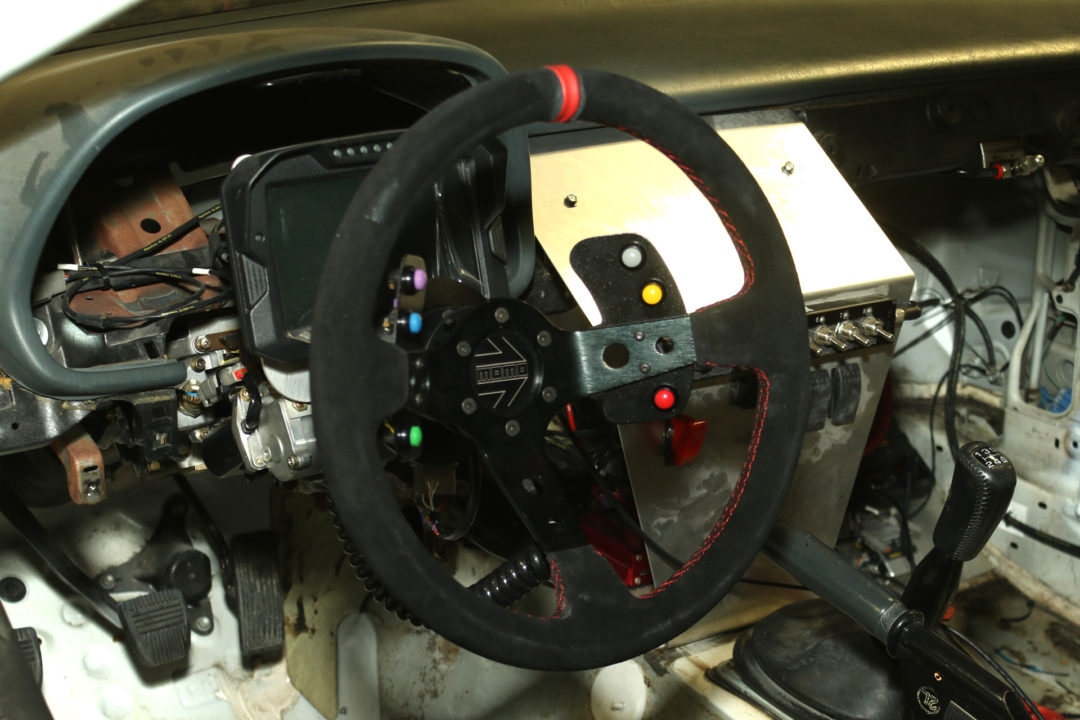

With the engine bay wiring all neatly tucked in, it was time to move on to the rest of the car. We bounced around here and there as it made sense. There’s quite a lot of harness in the cabin, and it should also be neatly tucked away. A large portion of the cabin wiring would be hidden behind the dashboard, but that doesn’t mean that it should not be neatly routed and secured.

We started by plugging in the main connections on the Racepak Smartwire, and then we would move onward and outward from there.

We started by plugging in the main connections on the Racepak Smartwire, and then we would move onward and outward from there.All of these devices have their own grounds, so it would be important to bring them all to the same point.

All of the miscellaneous grounds are stripped and prepared to be inserted into a single ring terminal.

All of the miscellaneous grounds are stripped and prepared to be inserted into a single ring terminal.

The cabin ground ring terminal is prepped with glue line and all of the individual wires are covered in DR25 heat shrink tube to make a nice bundle.

The cabin ground ring terminal is prepped with glue line and all of the individual wires are covered in DR25 heat shrink tube to make a nice bundle.

The front firewall panel has the holes for the three circular milspec connections. But the flanged connectors have small retention pins that must be able to pass through the hole. Tom is filing a small notch to accommodate.

The front firewall panel has the holes for the three circular milspec connections. But the flanged connectors have small retention pins that must be able to pass through the hole. Tom is filing a small notch to accommodate.