Improving Dai Yoshihara’s Formula Drift Engine Wear With WPC Treatment!

The world of Pro Drifting is a brutal place for machinery. Since I started my involvement with Pro Drifting 10 years ago, I have been amazed by the appetite for parts a pro car possesses. In all of my engineering career, I have yet to be involved with a motorsport that eats more expensive stuff on a regular basis.

In drifting, the engine is the center of a lot of this abuse. Modern drifting requires an engine to produce around 1000 whp with a wide powerband, a lot of torque and fast throttle response. Having more power than the next guy isn’t as important as having sufficient power. Sufficient power is enough power to keep large sticky tires spinning on demand no matter how tacky and rubbered in the track is and how tight the chassis is adjusted.

Because the engine is operated at or near full throttle for as long as a minute per run at high revs, even bouncing off the rev limiter while continually being loaded really hard, wear on the engine’s parts, in general, is greatly accelerated. Previously our team’s engines were built by a famous engine shop who charged a fortune. Our engine life was pretty short, we would have to change motors halfway through the season and that engine would be pretty hammered.

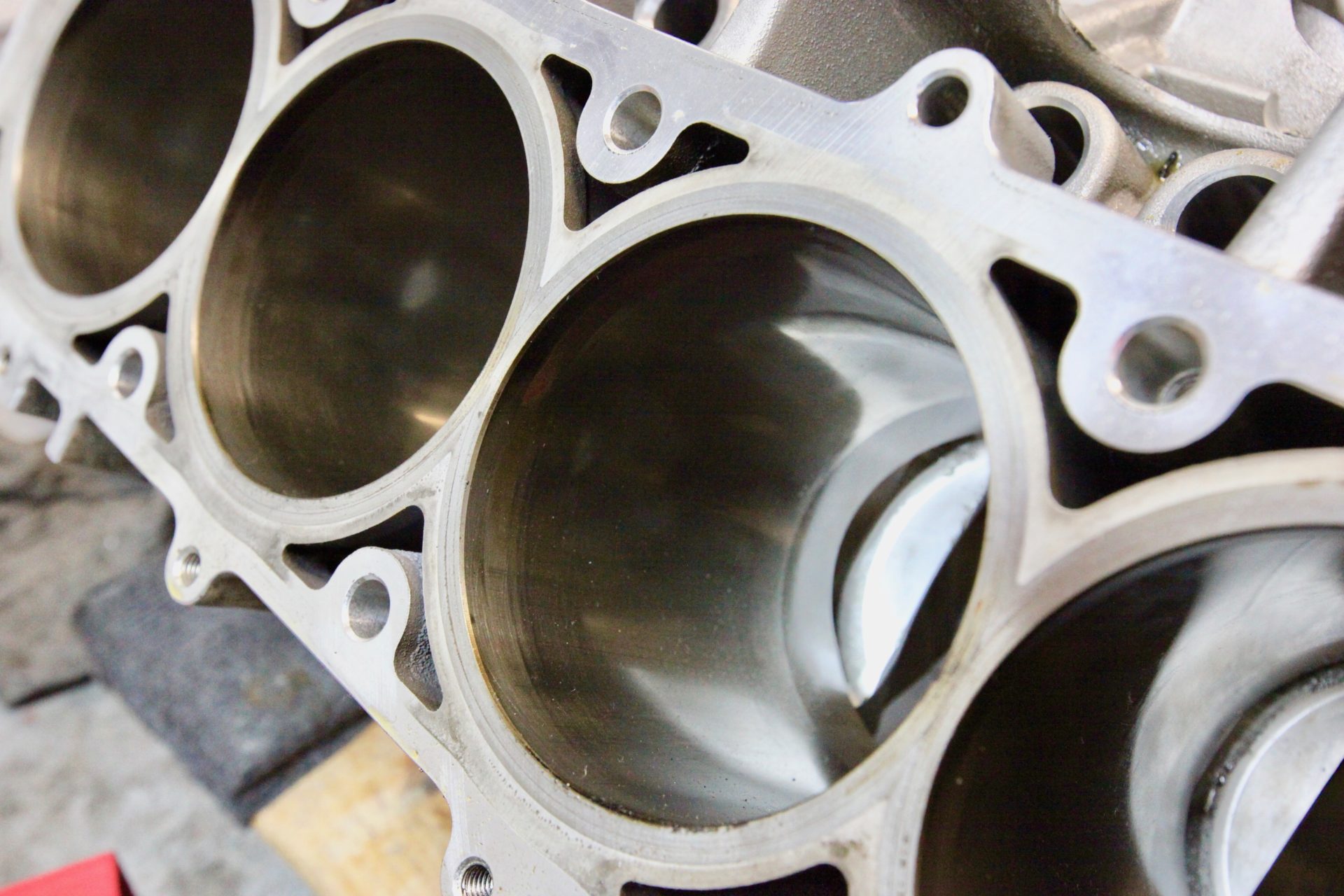

Pistons and cylinder walls would be pretty scored and beat up, in need of boring the next size over. The engine would leak down poorly, the valvetrain would be shot as were the engine bearings. Well, I thought that the MotoIQ Garage could do better and we have since taken over Dai’s engine program.

Since we have been engineering and building the motors, we have not had a major engine failure that caused any damage to the engine at all, and we have more than doubled the time in between servicing engines. Surprisingly, our engines can last more than a season of brutal Formula Drift abuse.

I am convinced that a lot of the secret of our engines durability is our extensive use of WPC treatment. Check out some of the stuff in one of our well-used engines below. This engine is one that has seen over a season and a half of use. This is the whole season plus a lot of testing and demo runs. The engine ran great, had great oil pressure and leakdown when it was pulled and disassembled for inspection and rebuilding.

For an article on how WPC Treatment works check this out!

Another Amazing WPC Treatment success story that we experienced.

On our previous motors built by the famous and expensive engine shop, the piston skirts were well worn and heavily scored. With long stroke motors, there was a lot of side load on the piston skirts, even with long rods. The old motor had an 800 rpm lower rev limit and half the use time before it wore out. With WPC treatment, the piston in the MotoIQ built motor looks almost new!

There was some light burnishing of the coating in some spots, but the bearing material was in great condition considering the amount of hard use the engine had on it. This was the worst of the bearings. We have been having great luck with King Bearings and use them for many MotoIQ Garage engine builds.

The newest King Bearings have an improved nano ceramic composite coating that is load bearing and greatly improves the bearings’ capacity and life. We will be starting to use these bearings starting with this engine.

The bearings have not been WPC treated, but the crank journals have, which in turn helps the bearings’ life as well.

There is very little thrust wear on the skirt, amazing considering the long stroke. This is less than half the wear we would see previously.

2 comments

I would like to know more about WPC.

This is wonderful technology.

How Can I get benefit of WPC Technique and what will be your terms & Condition.

The link to WPC and articles explaining about WPC in detail are in this article.