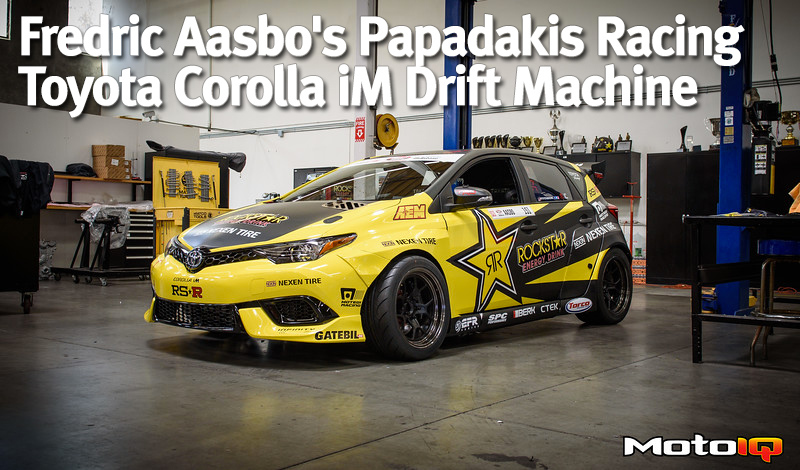

We Look Inside Fredric Aasbo's Papadakis Racing Toyota Corolla iM Drift Machine

It is really hard to build a competitive car in Formula Drift nowadays. The rules set is mature, and the competition is ruthlessly tough. When even the best teams develop a new platform, it can take a whole season to sort a new chassis out. A radically different chassis can take a couple of seasons for even a top team to get competitive. Not so for Papadakis Racing and their Rockstar Toyota Corolla iM that they built for 2015 Formula Drift Champion Fredric Aasbo.

In a feat of engineering, Stephan Papadakis and company has built a car that is an entirely different platform that has proven to be extremely competitive right out of the box. Having a brand new car on an unproven platform be immediately competitive has not happened until now in the modern age of drifting, which I consider to be post-2009.

It also helps to have a mature team and Papadakis Racing's crew dates back to the days of import drag racing, where Stephan was always successful and could be counted on to turn out innovative and well-engineered cars.

Stephan was kind enough to let us dig deeply into this marvelous machine and give us full disclosure on its innards and specs, so without further adieu, let's go!

The engine's block is sleeved by Golden Eagle with 1/2″ ARP 625+ head studs and billet main bearing caps and contains a Sonny Byant Billet stroker crank. Forged 10.5:1 JE Pistons are hung on Carillo rods with Calico coated ACL rod bearings and OEM Factory coated mains. The factory MLS head gasket is used although additional coolant passages are drilled in it for improved cooling.

The engine's cylinder head is ported by Portflow Design who also does the special radius valve job with wider than typical 45-degree valve seats for improved reliability. The head has Supertech intake and exhaust valves with the intake valves made of 21-4N stainless that is black nitrided. The exhaust valves are made of heat-resistant Inconel with a sodium filled stem.

The engine's cylinder head is ported by Portflow Design who also does the special radius valve job with wider than typical 45-degree valve seats for improved reliability. The head has Supertech intake and exhaust valves with the intake valves made of 21-4N stainless that is black nitrided. The exhaust valves are made of heat-resistant Inconel with a sodium filled stem.The head is machined to use larger valve springs to accommodate the 9000 rpm rev limit without float. Papadakis Racing titanium retainers are used. The head has been converted to use mechanical lifters and the custom roller cam followers are shaft mounted for additional high-rpm stability.

The camshafts are a special grind developed by Papadakis Racing and have 0.450 lift and 232 degrees of duration @0.050″. Cam timing is fixed on the exhaust side while the intake uses the factory VTC system allowing the AEM Infitiy ECU to control the intake cam with 45 degrees of command authority.

The engine uses the stock Toyota/Denso direct fire coils controlled by the AEM Infinity ECU. This has enough juice to fire the plugs even with a lot of boost pressure and nitrous induced cylinder pressure.

For drifting, fast throttle response from the engine is very important for controllability when being completely sideways in close proximity to another sideways car. The EFR9174 has many spool time and lag reducing feature starting with a high flow, forged billet CNC-machined extended tip compressor wheel. The forged billet wheel has better mechanical properties, such as superior grain and grain flow. This makes the compressor wheel stronger.

The improved strength from forging allows the use thinner blades for better flow, and the extended tip gives the inducer more “bite” which also speeds spool. The stronger material also allows the designed to shrink the hub size for better aerodynamics and flow as well.

The billet compressor wheel sits in a ported shroud compressor housing, which fights compressor surge by allowing inlet air to recirculate through the compressor as the flow is starting to back up. This is especially important when running a turbo with nitrous as the Papadaki IM does. The extra exhaust gas volume that nitrous creates can drive the turbine hard overspeeding the compressor past the surge line at lower rpms and put it into damaging surge, which the ported shroud housing can prevent.

On the turbo's hot side, a CFD designed investment cast stainless steel exhaust housing with a Titanium Aluminide super lightweight turbine wheel provides the drive for the compressor. The turbines exotic intermetallic material reduces rotating inertia to a minimum. Titanium Aluminide has the properties of both a metal and a ceramic, having the strength and ductility of a metal with the lightweight and temperature resistance of a ceramic. This lightweight turbine wheel combined with the twin scroll housing can reduce spool time by over 30 percent.

The final part of Borg Warners lag reducing technology is the EFR9174's ball bearing center section which reduces friction and improves life under high thrust loads caused by high boost and nitrous. The spool time can be improved as much as 20% by using ball bearings here.

Twin Scroll turbos utilize pulse energy of the engine to hit the turbine with 4 discrete, evenly spaced pressure pulses to get the most drive possible out of the exhaust stream. A twin-scroll system can speed spool time by as much as 25%.