Project GD STI: Making the Front of the Car Stiffer with Ultra Racing

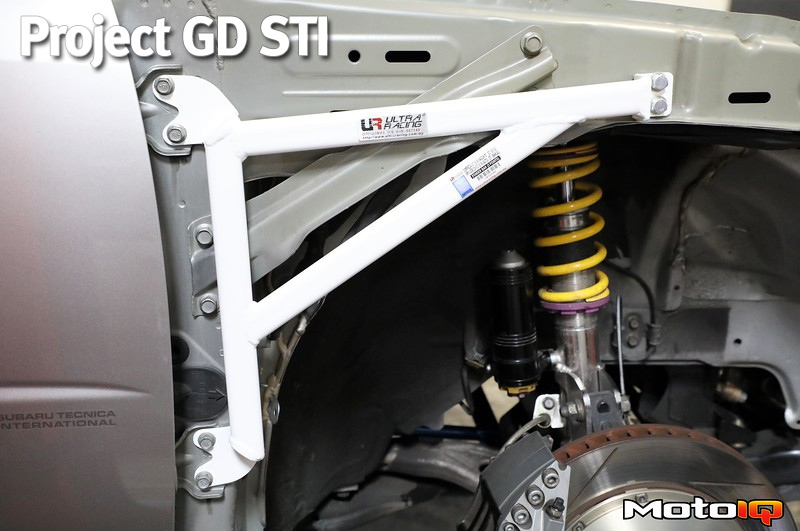

In the last installment of Project STI, we had greatly increased the chassis stiffness with a full complement of Cusco braces. From our EVO project, we had found that on the CT9A chassis, the braces that did the most were the fender braces that add reinforcement from the strong door hinge area to the top of the shock towers. From this experience, we wanted to add similar braces to our STI.

One of the reasons that we have been impressed with the newer VA STI is the stiffness with its integrated shock tower, firewall, and ring module chassis. We want to try to emulate that stiffness as much as possible with the old GD. Now that is not possible short of a weld-in cage, but we want to see what streetable solutions we can come up with.

We were able to find 3 possible fender brace sets for the car on the internet. Several companies sell beefed up versions of the stock fender brace that reinforce the corner from the firewall to the top of the unibody in between the firewall and the shock tower. We didn't didn't want to use this type, as we wanted to add stiffness all the way to the shock tower.

The first promising brace we looked at was made by GT Spec, which was a sturdy, triangulated tubular brace that replaced the stock part. However, GT Spec has apparently gone out of business and no one answered our phone calls or emails in the contact section of their web site. The second brace we looked at was made by NAMS, a Japanese company. NAMS made the brace for our CT9A, but we did not like the design for the GD chassis because it was not triangulated. It was a simple V-shape tubular brace reaching from the door hinges to the shock towers. It also had the super expensive JDM price.

Finally, we found the brace made by Ultra Racing in all places but Amazon.com. Normally we stay away from this sort of product found online like this, as often the parts are cheap knock-offs. We don't have a problem with this, as long as it's not a rip off of an established product and if it is decent quality.

We liked the Ultra Racing's triangulated design, and it was relatively inexpensive. Ultra Racing also had a US distributor as well, so that was helpful. Looking at their website, they have an assortment of braces for many popular Japanese cars.

Read more about Project GD STI !

We liked the fact that the braces were triangulated and that they were designed to be used in conjunction with the stock factory braces instead of replacing them. This spread out the loads and helps with stiffness, particularly in torsion.

Howard started by removing the front grill by prying off the plastic mounting clips. The front end of the STI is largely held on with plastic clips instead of bolts. Martin isn't being helpful at all.

5 comments

Aww shit what happened to the old comments?! There was good data in the comments!!!

yeah sorry about that but as we transitioned to this new site it became clear that transferring the user accounts from the old site was a large and difficult undertaking. Since we didn’t bring the user accounts over, the comments couldn’t come with them either.

I know this is a slightly older wright up, but I wanted to point out that these braces were installed with the car on jackstands, this could have been the culprit for aligning the door as the chassis flexes a bit to where the jack stands are. Same reason why its typically common to weld in a roll cage when the car is sitting on leveled ground.

This is not the case in this car, maybe old cars. It’s just never easy to line up doors so you always have to be careful or you end up chipping the paint, etc.

It looks like Ultra Racing has discontinued these braces. In your research, were there any other braces like these that stood out as maybe equal to or at least 2nd place compared to these? I was literally about to order some for my 04 and saw the “Discontinued” sign 🙁