Project STurdteen: Prepping SR20DET Heads with Portflow Design

For those of you who have been keeping up with my Project STurdteen drift car, you will see that we spent a good amount of time overhauling the suspension and making small gains with some bolt-ons. After I took her out for my first track day, I unknowingly lost the dipstick at some point and discovered a slight ticking noise in the head. After conducting a leak-down test, we discovered that two of the cylinders were down over 25%. In other words, the Turd’s heart was a bit worn down and it was time for a rebuild!

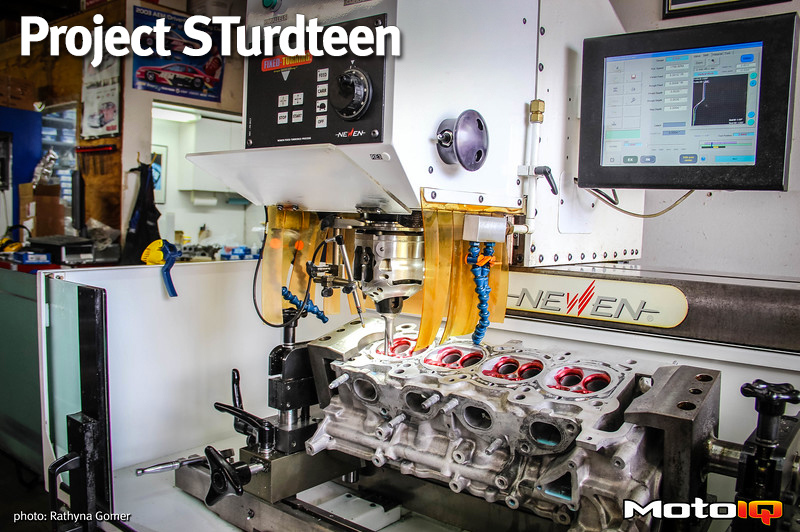

Before diving into the block, we decided to work with the amazing Tom Fujita from Portflow Design to begin working on my SR20 head. Portflow designs uses the Newen valve seat cutting machine.

The Newen is innovative as it does not use stones or cutters like the traditional valve seat cutting machine used in valve jobs. The Newen is a CNC style cutter that uses a tool bit to shape the seat and surrounding head for optimal flow. Instead of abrupt angles like old style cutters, the Newen makes a smooth radius for best flow.

The Newen also blends the valve seat into the combustion chamber and the port, eliminating turbulence causing steps. If done correctly, a Newen valve job can make much of the flow gains that a fully ported head can make!

We didn't show it, but my head was pretty hammered. This required getting new bronze valve guides from Supertech to go along with my Supertech stainless intake valves and heat-resistant Inconel exhaust valves. SR20's are pretty hard on guides, so this is not unheard of for an SR that has seen a rough life.

3 comments

This is another project that vanished I wish we could see again

Questions!, who made the valves or how were the valves made for the newen cut seats?

did you read the article at all?