Project [Rotary] FD RX-7: Part 2 – Fuel System (Engine Side)

There are three key ingredients for combustion in any gasoline engine: air, fuel, and spark. Parts 2 and 3 of this project will focus on the fuel component of this recipe. Rest assured, this won't be your typical run of the mill RX-7 fuel system.

The RX-7's factory fuel system is somewhat unique because it utilizes staged injection. It consists of two 550 cc/min side feed “primary” injectors that run the engine when little fuel is required (idle, cruise, etc) until they reach a programmed threshold. When this happens, two 850 cc/min side feed “secondary” injectors kick in to provide more fuel. At this point both the primary and secondary injectors run together to supply the required fuel.

The FD RX-7's factory fuel system consists of four side feed injectors. The short rail houses the two 550cc primary injectors and the long rail houses the two 850cc secondary injectors.

Most aftermarket fuel systems utilize the factory primary rail populated with either the factory 550cc or 850cc injectors, while the secondary injectors and rail are replaced with an aftermarket rail and a pair of high flow top feed injectors. For a long time the high flow secondary injector of choice was the 1680 cc/min Bosch EV1 (160 lb/hr for those of you who are SAE inclined). One complication with using these injectors is that they are low impedance which most aftermarket ECU's for the RX-7 can't handle natively. There were two ways to address this, wire in an injector driver box designed for low impedance injectors or the much cheaper, easier, and more common way of wiring in a resistor to increase the impedance of the fuel injector circuit.

Again we will fast forward to the present where we don't have to do silly things like wire in resistors because technology has improved and we have significantly better options for high flow injectors. In this case we're talking about the modern Bosch EV14 injector; a compact, high impedance, high flow injector with a great spray pattern that is much easier to control than the old EV1 injectors (especially at low duty cycles). We can then take it one step further and use dynamically flow matched pairs of Bosch EV14 injectors from Injector Dynamics.

This injector combination (885 cc/min primaries and 2225 cc/min secondaries) yields a total injector flow capacity 6220 cc/min, which is immense when you think about gasoline fed piston engines. However, because rotaries require more air and fuel than piston engines to yield the same power (read higher BSFC to the engineers out there), this means the power potential of this injector combo isn't quite as impressive as the flow rate makes it sound. With some assumptions and a maximum injector duty cycle of 85%, this injector combination should realistically supply enough gasoline for somewhere in the low to mid 600 wheel horsepower range.

The next step in the process is to mount these injectors. In the factory fuel system, the primary injectors spray fuel directly into the center iron housing of the engine, while the secondary injectors spray fuel into the outer runners of the lower intake manifold (entering the engine at the front and rear iron housings). Since the primary and secondary injectors are in different locations, separate fuel rails are required, which is a driving reason for many people to only upgrade the secondary injectors and rail. As stated earlier, we are doing things a bit differently for this build. In Part 1 of Project FD RX-7 we talked about the Xcessive/GZ oil pan and its benefits, this time we are introducing their lower intake manifold.

Xcessive Manufacturing's cast aluminum lower intake manifold. We had it thermal barrier ceramic coated to help keep radiant heat from the turbo and engine out of the intake air.

This intake manifold incorporates several benefits that can be taken advantage of. The most important advantage is the fact that this manifold eliminates the non-symmetric intake path of the OEM manifold and increases the airflow rate up to 13%. Another less significant advantage is that this manifold permanently removes several emissions mounting features. This could also be considered a disadvantage if you are trying to meet specific emissions requirements.

Comparison shot between the OEM and Xcessive lower intake manifold. Notice the symmetric intake path between the front and rear rotors on the Xcessive manifold. Also, the Xcessive unit eliminates the need for block-off plates for the deleted emissions items.

The other major advantage of this intake manifold is that it features four injector bungs (one per runner), which increases the possible fuel system configurations. One example is E85 users that opt to both utilize the primary injector ports on the center iron housing with “normal” sized injectors and populate the four ports in the lower intake manifold with equally sized high flow injectors, giving them the ability to flow the volume of fuel that E85 necessitates.

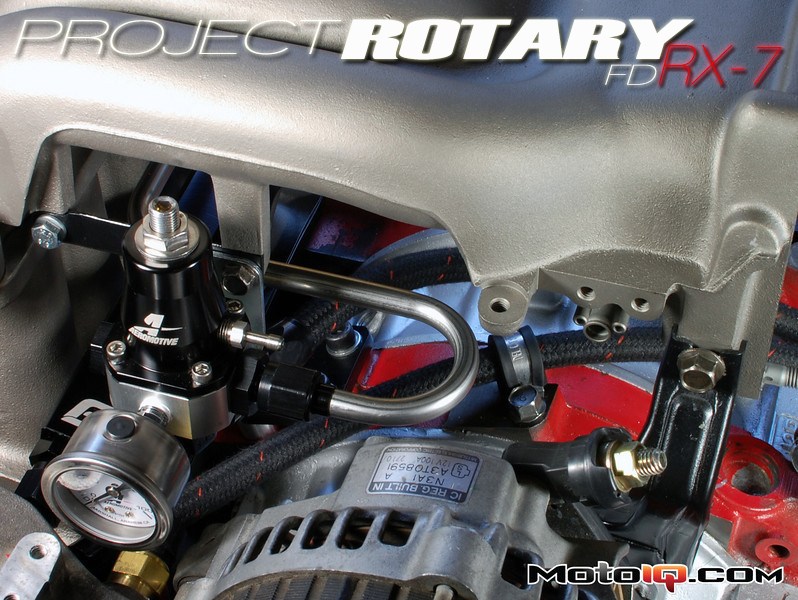

In the case of this project, since E85 is not in the plans, the primary injector ports won't be used at all and the four ports in the intake manifold will house both the primary and secondary injectors. This type of configuration requires a four port fuel rail and a solution for blocking off the primary injector ports.

1 comment

Where can I purchase these primary plugs?