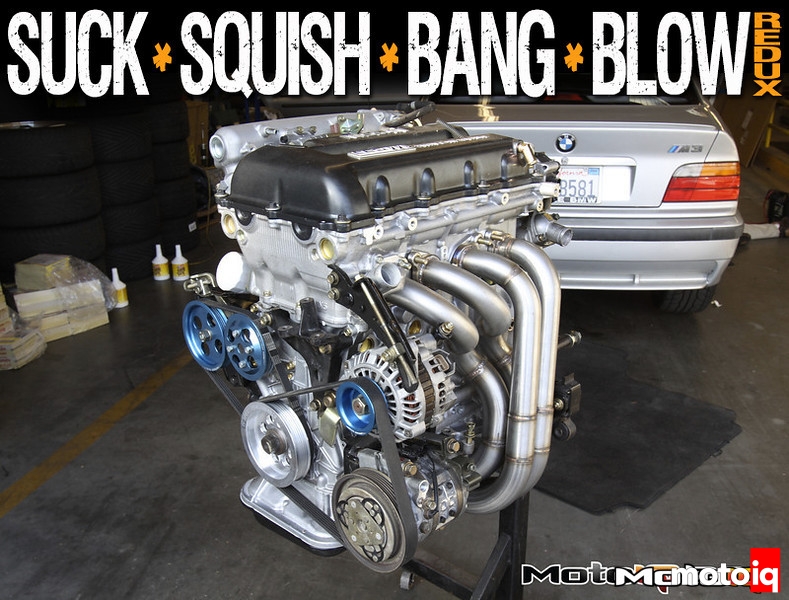

Suck Squish Bang Blow: All You Wanted to Know About How Headers Work (Part 1)

by Mike Kojima

Headers are one of the most common and basic of your bolt on mods, however very little is understood about how they actually work. How and why headers work is an arena full of old hot rodders and internet keyboard guru’s tall tales and myths. We can easily understand why this is true as there are not many accurate stories on the net on how headers actually work. Most of us know that headers can produce substantial amounts of power on a motor with very few negative compromises. Properly designed headers work well in producing extra power with without many of the typical negative side effects of power mods such as loss of low end drivability and mileage reduction. Headers are a rare, win-win modification with hardly any negative trade-offs. This makes them a mod that is almost essential for any engine build-up from serious to mild bolt on.

More on Mike's continuing series on how engine stuff works.

|

| This is a stock exhaust manifold off of a typical late model car. It was primarily designed for good cold start emissions as the catalytic converter is very close to the exhaust ports. Most of a modern car's emissions occur during the first few seconds after cold start so speeding the amount of time it takes to light off the cat makes a huge difference in overall emissions. You can almost bet that a header will help this car. Some cars, like recent Hondas take this to an even greater extreme where the exhaust runners are cast into the head and are extremely short. Good for cat light off but impossible to modify. |

For space, cost and catalytic converter light-off reasons, most cars come from the factory with crude, cast iron, log exhaust manifolds. A log manifold is simply a cast tube with short, stubby legs connecting the exhaust ports to the main tube. Once the tooling is designed they can be made by the thousands for very little. Besides being cheap, a log manifold is also good for conserving exhaust heat to quickly light off a catalytic converter during cold starts. A cast manifold can be compact, hugging close to the cylinder head, preserving valuable under hood space within today’s crowded engine compartments. All of these attributes are important to an OEM engineer; however a log manifold is detrimental for power production which is often a secondary concern to the OEM designer. A few of today's newer cars come with more efficient tubular exhaust manifolds most of which have short runners and crude stamped transitions. Not the greatest for performance either but much better than a simple log. Most OEM tubular manifolds are double walled and have insulation sandwiched in-between the walls to speed cat light off. In short, an OEM manifold has many design parameters to fulfill with power production perhaps not as high a ranked priority.

|

| This is a log manifold where very short runners dump into a larger tube that collects all of the exhaust gasses. The stock manifold is on top and an Extrude Honed ported version is on the bottom. As you can see a log manifold is hurting from both a flow and an overall tuning perspective. |

What exactly is a header? Let’s first start off with the most basic of basics. By the enthusiast definition, a header is an exhaust manifold fabricated from tubular sections of pipe. Full radius mandrel bends are preferred so the pipe’s tight radiuses will not be crushed down promoting better exhaust flow and more equal flow from cylinder to cylinder. Each individual exhaust port is treated to its own separate primary runner of close to equal length instead of merely dumping into the shared main pipe of a log manifold. The equal length, or close to equal length primary pipes converge at a single, larger diameter point or collector. The collector then leads to the main exhaust pipe.

|

| You can see how the stock manifold on top is really corked up compared to the Extrude Honed part. |

An old hot rodders tale is that headers produce more power by reducing backpressure. Intuitively, when looking at a kinked up stock log manifold this seems correct but backpressure reduction alone is not the main reason why headers work so well. Case in point, there are a few cars like a D15/D16 Honda engine or the DOHC Ford/Mazda V-6 engine where adding headers to an otherwise stock engine produces very little additional power despite really crappy looking stock exhaust manifolds. You might wonder why this is so.

|

| More comparison. These manifolds were on a turbo engine so increasing the flow really helps power even though it has no effect on pulse tuning. |