Project Honda Civic EJ: Building the B18C1 Part III

By Chuck Johnson

Photos by Joe Lu

Last we left off, we had just figured out how to improve the rod ratio of Project Civic's B18C1 through the use of a Nissan QR25DE spec rod from K1 Technologies. In short, to make this rather unorthodox marriage of Nissan and Honda components work, the factory B18C1 crankshaft's rod journals were modified along with the big end of the QR25DE connecting rod. To help ensure marital harmony for years to come, a set of factory Honda connecting rod bearings were WPC treated and then installed in between the Honda crank and Nissan rod. WPC treatment of Honda bearings can improve load bearing capacity by as much as 25% as well as reduce friction. The crank was also WPC treated as well to improve wear, increase fatigue strength and reduce friction. For more details on how we made this long rod combo work, you can read up on part 2 of our engine build here.

You can read more about project EJ Civic here!

|

With the crank and rod situation figured out, there remained one missing link to make this exogamic marriage of Honda and Nissan components complete. Without a piston that is shorter in compression distance, none of this long rod business would actually work. Compression distance, also known as pin height, is the distance from the center of the piston's pin bore to its deck. To figure out the new necessary compression distance is simple and can be calculated using the formula below.

(Block Height) – (Rod Length) – (½ Stroke) – (Deck Clearance) = Compression Distance

In our case, the new compression distance for our long rod pistons worked out as follows:

(8.340″) – (5.630″) – (3.433″/2) – (.005″) = .989″ Compression Distance

A compression distance of .989″ is pretty short for an automotive street application. Actually, it's about as short as one can go without ditching a compression ring, using pin buttons, or having an unacceptably small wrist pin diameter. With the .989″ compression height we didn't have to go to any of those extremes; however, the pin bore was run into the oil ring groove and it was necessary for us to run a rail support.

|

| A detent as well as tension, locks the rail support in place and keeps it from rotating out of the opening. |

In cases where the pin bore crosses into the plain of the oil ring groove, an additional steel rail called a “rail support” is installed underneath the oil ring assembly. Appropriately named, a rail support does just that, supports the oil ring rail and assembly across the opening in the ring groove caused by the pin bore. Absence of a rail support would cause the oil ring assembly to essentially unwind itself and spiral through the opening in the ring groove. Simply put, this would lead to disaster.

|

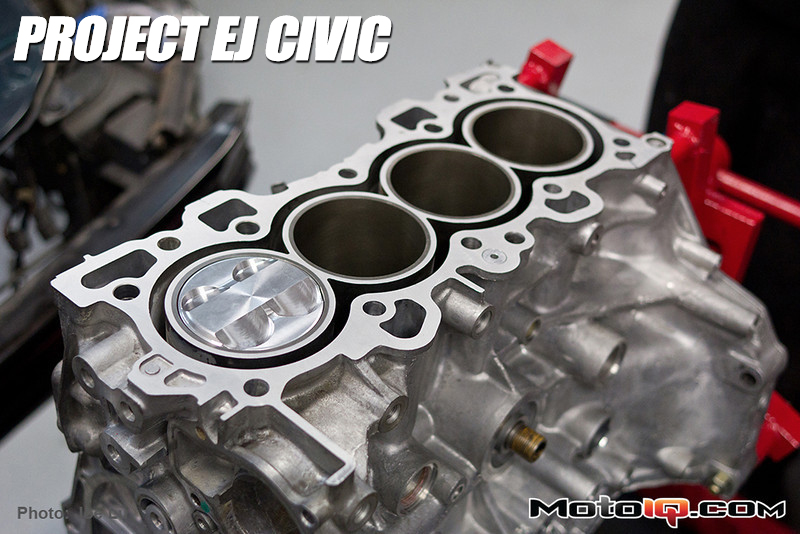

Having figured out conceptually how we were going to run our short .989″ compression height, we turned to JE Pistons to design and manufacture a set of forged pistons for our long rod B18C1. Since our B18C1 had seen over 200,000 miles of service, we decided to bore and hone our block to 81.5 mm before putting Humpty Dumpty back together again. One of the side benefits of this increase in bore was a small increase in displacement of 22 cubic centimeters. Hey, it's not much but we'll take what we can get since this motor will be sucking instead of getting blown. We also WPC treated the bores after machining for less ring and skirt friction and longer life. The WPC give longer ring, bore and piston life as the treated surface retains lubrication better and is inherently harder and slippery due to the process characteristics.

At the same time, we had JE pistons increase the compression ratio a point and a half to 11.5:1, which should still be street-able even with California's lousy 91 octane gas. To round out the piston's features, JE Pistons coated the piston's skirts and machined an accumulator groove into the second ring land. An accumulator groove is designed to increase the area under the first compression ring and reduce the chances of pressure build up and ring flutter at high RPM.

|  |

A 9310 alloy steel wrist pin is used to join the K1 Technologies connecting rod with the forged JE piston. Instead of the factory 21 MM diameter pin though, a 20 MM sized pin was selected. Why? A 20 MM pin is what the QR25DE uses from the factory. With a decrease in wrist pin diameter, comes a slight decrease in strength and stiffness. To compensate, a slightly thicker wall wrist pin was used in tandem with the higher strength 9310 material.

With all of the hardware now sourced for our bottom end, we were almost ready to begin its assembly. Before beginning the assembly, since we wanted to be cautious that we had removed all of the WPC media from the block, we sent the block out to be ultrasonically cleaned and then gave it a good scrub down using a plastic bristled brush and liquid Tide. It's important to hit the cylinder walls with WD-40 immediately after to prevent corrosion. Lastly, we used smaller brushes to clean out the oil galleys of the block and also gave all of bottom end components one last cleaning.