Hooker Headers Nissan S Chassis LS Swap Headers and Motor Mounts

By Mike Kojima

Hooker Headers has been a name that has been long associated with good old Detroit iron. Lately it seems that Hooker has noticed the trend of blending American muscle with Japanese chassis, especially the popular swap of putting an LS engine in the Nissan S chassis.

|

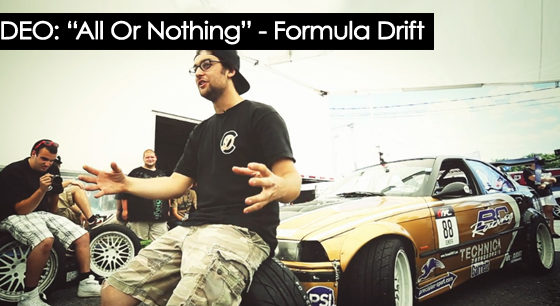

| The Hooker S Chassis headers are shown here on Formula D Pro, Matt Powers' practice car. Matt's car is an S14 but not nearly as trick as his competition car. Matt's practice car was used to demo the new headers because it more closely resembles something a typical customer might use, unlike his ultra trick competition car. |

Although popularized by drifting and made acceptable by Dai Yoshihara's ride, putting an LS in an S Chassis makes sense. The compact and feathery Chevy LS is nearly the same weight as an SR20DET and lighter than the iron block stock KA24DE. At up to 427 cubic inches or 7 liters it packs a lot of displacement in a small package and it fits nicely into the engine bay.

|

| Matt's practice car is still quite a nice piece. It uses a GM Performance Parts LS 376/525 crate engine. This engine makes 525 hp and 489 lb/ft of torque right out of the box from GM. It is stock except for a K&N air intake, a Holly HP EFI ECU and of course a set of the new demo Hooker Headers. Matt's engine swap uses good parts to center on bulletproof reliability using Earl's hose, firesleeve and hose ends, an Earl's oil cooler and a big Ron Davis radiator. The fabrication was done by Costa Gialamas of Gialamas Technical Innovations. |

An LS powered S13 or S14 is a reliable and fun car with about the same or better balance than stock.

|

| The Hooker Headers are made of quality 304 stainless steel and are tig welded. They will also be avalible in a lower cost mild steel version as well. |

Due to his relationship with Holley, Matt was fortunate enough to receive a pre-production set of these new headers for testing prior to them being released for full production… the same upgraded components seen on this set will be used in fabricating the production versions.

|

| Some nice details of the investment cast scalloped flange with clean tig welds. |