Project Nissan Sentra Spec-V Part 7: Installing a Turbo System

By Mike Kojima

Some good news for our project is that Redline Track Events has revamped their rules set so our Spec-V is now eligible to run in the less exotic Modified class. Now we have a chance since we no longer have to compete with mega buck efforts like Chris Rado's Scion TC monster. The car was designed to run DOT radials so now we can run in a class where they are required. This will also cut our tire budget. Now that our car has a chance of being competitive we will turn our attention to our turbo system.

|

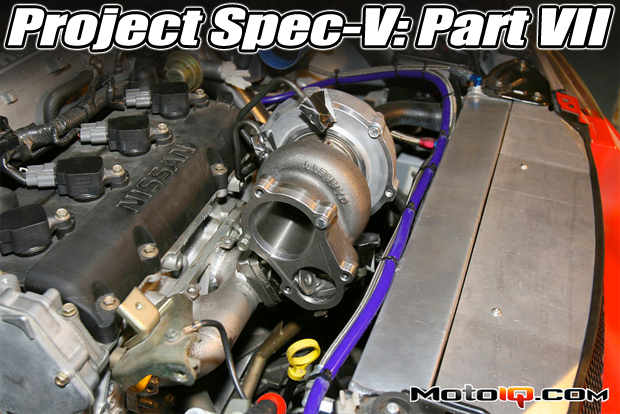

| We had started our Project with the intent of using a fast spooling Garrett GT28RS Disco Potato turbo. It became quickly apparent that we would need much more than the DP's 350 hp capability to be competitive in Time Attack so we changed courses in mid stream and decided to run a bigger turbo, a GT30R. The compressor on our GT30R dwarfs the GT28RS. |

|

| The Turbine discharge is a lot larger for a lot more flow as well. Note the divorced flow path for the internal wastegate. |

Since the long stroke QR25DE does not like high rpm, we have chosen to limit its maximum revs to 7000 rpm and make power by adding turbo boost. Jim Wolf Technology designed our turbo system to produce power over the widest possible range of RPM rather than peak power. The JWT system was also designed for simplicity, lightness and reliability over maximum power.

|

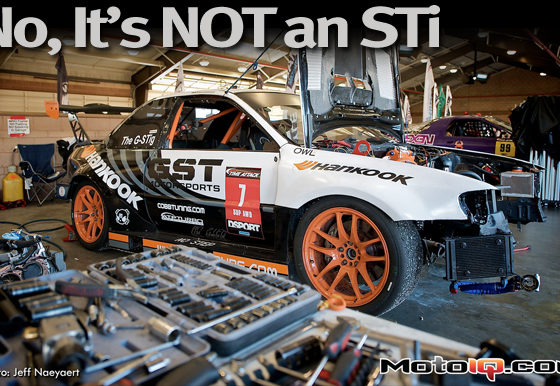

| It was apparent that our newly built JWT experimental turbo system was going to be massively outgunned on the track even though it would have been wonderful on the street! |

|

| Goodbye small GT28RS, hello GT30R! |

We had started with a smaller turbo, an uber fast spooling Garrett GT28RS otherwise known as the Disco Potato. This turbo can produce a maximum of 350 hp or so. We quickly realized that this was probably too little horsepower for us to have any hope of being competitive. This lead us to scrap much of our original system and upsize to a Garrett GT30R.

|

| Burns Stainless supplied us with thin wall 90 degree and straight 321 stainless tubing. With a 3” radius the burns 90 is extremely tight. With exotic 321’s superior properties, you can get away with real thin tubing for less weight. 321 is expensive, more difficult to fabricate and harder to weld but it is a superior material. |

|

| We also used these stainless steel doughnuts from The Chassis Shop. Doughnuts are made by welding two stampings together to create a tighter longer radius bend than can be made by a mandrel bend. These things can help you package many sorts of things in tight places. |

We could have gone more exotic and designed an equal length tuned header with external wastegates but we jointly decided with JWT that we could easily make more than 500 whp with a very simple system using a log manifold and internal wastegate. In racecars simple is better. A log manifold packages much better, is less likely to crack, can spool faster and is lighter. An internal wastegate makes the exhaust plumbing simpler and more reliable. We also felt that it would be hard to get more than 500 whp to the ground in a FWD car with the technology we could afford. It would also be difficult to get the drivetrain to be reliable with more power than this as well without exotic and expensive technology.

|

| Mike Smith, Jim Wolf Technologies master fabricator starts by test fitting our new turbo to our old manifold. |

|

| Once he has an idea of where the new turbo can fit, he gets a rough idea of where the larger T3 size flange has to fit. |

5 comments

Mike, how is the time attack coming? For years I’ve been toying with the idea of a primarily off the shelf parts V12 with enough capability to be worthy of the investment. Sure anything V12 would be cool but for genuine interest, I need two things. For larger displacement, (the impossible find! Every OE is making baby bores for economy) that 87mm is the absolute “sweet spot” for single sparkolator flame front propagation, meaning lowest possible chance of detonation while still having room for valves. For displacement and having a minimal chance of detonation, I need a dual plug 4.5 inch bore. I’ll have to compromise with a single plug at 4.150-4.185 bore. Nissan has a 4.41 bore space, Mopar has a 4.46 bore space. The Mopar 3.5 SXT and 4.0 R/T Nitro have SOHC 60 degree blocks. Beefier than the Nissan with closed deck design. VQ37HR or VK56 heads oughta do.

The point is, I found your T/A build here searching for QR25 bore spacing, wuuuh waaah, too small. This is an awesome build! Can’t wait to see it go. I’m thinking of a LS mid sleeved VK56 for a 94 Sentra rwd conversion!! Lotta work, but cool factor off the charts. Wheel well and opening hackery for to the Nth degree to get any decent size diameter tires.

When is this thing gonna make some runs?

We scrapped the car mostly because the QR engine is a piece of trash and there was no interest in the car besides maybe 50 people in the world which made sponsorship impossible. Basically what you are planning isn’t really possible and your assumptions of bore size and understanding of bore spacing are not correct either. Your considered build won’t have any sponsorship or fan interest either. It is also several hundred thousand dollars to do what you think you want to do. I suggest sticking to cars that have more interest and technology that is off the shelf.

Well I’m interested in what you have to say about my following comment…

I’ve already poured a couple thousand dollars into my qr25 build with over two years of research and it might very well be a waste of money but it’s one I’ll see through. I just got my stage4 clutch from 2j-racing, they have been a big help to fill in some of the gaps. I to am aiming for 400hp-450 safely but for street, still taking the massive extra steps to make my bearings happy and oiled. my last piece of the puzzle “was” going to be sleeve the block but I see you used a different method, one that I only heard of a couple weeks ago. Now, I read you didn’t finish the project but how do you think the engine would have held up with the aluminum filled epoxy resin?

Hows your build coming Emily D?

I’m in the middle of my turbo build, shooting for 280hp on my 02′ with 34k miles and still running strong. Concerning your block try reaching out to VisionRacing, or better yet you can do a VQ swap with Nissformance kits.

Emily I actually finished my build..

but I had spent LOTS of money addressing the well-known issues of the engine.. plus all other things around the engine..

all I have to say is if you want to make power, there are cheaper ways, I was WAY to invested in the car, to just scrap it, so I saw the project thru and we had some failures and some wins!

since the car body isn’t in that good of a shape I am going to delete the rear bumper and put a crash bar like a drift cat (yes is silly, but I have the rear end look, I am also going to put a racing and ok, not to horrible of a wing on the car and black out the light lens..

you can kinda see the progress of the car on my Instagram

anuar.m.yanez that’s my handle.