Ask Sarah- DSM Fuel System Tips

By Sarah Forst

Dear Sarah

I read your last article about using a properly sized fuel system and wondered if my fuel system is adequate enough for when I finish my engine build. I have a 1995 Eclipse GS-T that I’m upgrading to the 16G turbo. Is there an easy way to determine how big of injectors or fuel pump I need so I don’t run out of fuel at full boost? Any other helpful hints?

David H.

Got a Tech Question? Email Sarah at asksarah@motoiq.com

The 1995-1999 (2nd gen) turbocharged Eclipse uses a Garrett T25 instead of the first generation Mitsubishi 13G and 14B turbos. The compression ratio was increased from 7.8:1 to 8.5:1 in the 2G’s in order to provide power with this smaller turbo but keep the turbo lag to a minimum.

Almost any turbo is an upgrade over the tiny, stock T25 which is limited to about 250 horsepower. Even though stock boost is rated up to 14psi, it barely pushes 10psi at redline. The stock blow off valve has such a weak spring it can’t hold that boost. The 16G turbo (TDO5-16G) with 7cm exhaust housing flows just over 500cfm and can boost over 20psi. The 2G Garrett turbo routes the intercooler hose differently and uses different water and oil lines than the 1G turbos so if you’re going to install a larger Mitsubishi turbo such as the 16G on your 1995-1999 Eclipse, you’ll need to make some changes. Road Race Engineering sells a full 16G turbo install kit that will simplify your life. The kit includes the 2 ¼” piping from the turbo to the stock intercooler, braided stainless steel oil supply line, oil drain line to oil pan, front and rear water cooling lines, and all gaskets and washers to complete the install.

|

| The 16G is a very mild upgrade for a turbo. You will have to do a bunch of stuff to get it to work on a 2G Eclipse so you might want to consider an upgraded one like this one from Forced Performance or even a bigger 20G. |

A turbo provides more air to the engine and requires additional fuel for safe, complete combustion. Depending on your boost, you will need larger injectors and a higher volume pump. Larger fuel injectors and fuel pump will require some way to control them.

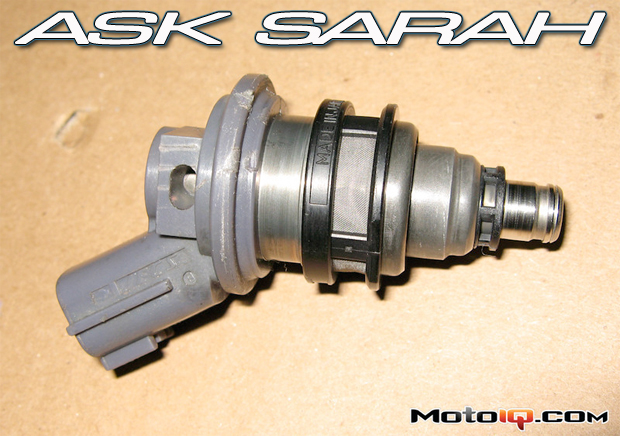

If you’re not a numbers person, I can give you generalizations. The stock injectors flow 450cc/min but give up around 14-15psi on pump gas. 550cc/min injectors such as those from RC Engineering, and a larger fuel pump will work for 16-18psi on pump gas and up to 21psi with race gas. If you’re boosting above that, you’ll need 660cc or 720cc injectors, a higher volume fuel pump, and a high volume fuel rail such as the one from AEM to deal with the additional fuel volume requirements. The stock 2G Denso fuel pump flows 130lph (liters per hour) at 43psi at 12.5 volts at the fuel pump, good for boosting up to 14psi. With these fuel pumps, flow falls off as pressure increases. Your options for upgrade include the Walbro 190lph (which is rated closer to 170lph for the same 12.5 volts) or 255lph (rated around 230lph). I would probably recommend going straight to the 255lph version.

Calculating your Fuel System

If you *are* a numbers person, you’re in luck- I’m about to get all mathematical on you! You can calculate what size injectors and fuel pump your engine will require once you figure out the expected horsepower you plan on making. Most turbos have fairly efficient compressors and the 16G has around 70% efficiency, which we’ll use to calculate how much power it takes to compress air. Based on your engine’s displacement, volumetric efficiency, and the turbo’s compressor efficiency, you can probably get to 380 horsepower with the 16G upgrade. This assumes 91+ octane unleaded pump gas and 0.6 BSFC for a richly tuned motor which is typical of a turbo on pump gas. Obviously using race gas with a leaner race motor tune would change these calculations but you should consider conservative tuning to have headspace in your fuel system.

|

| We like RC Engineering Injectors, they are high quality, good performing and relatively inexpensive. |

We can use this horsepower number to calculate what size injectors and fuel pump you’ll need. Injectors are rated in either lbs/hour or cc/min. Let’s calculate injector size for our horsepower by dividing the BSFC (Brake Specific Fuel Consumption) by the number of injectors, and then multiplying that by the expected horsepower. Solving for injector size:

Injector size in lbs/hr = (0.60 / 4) * 380 horsepower

Injector size = 57.4 lb/hr

This assumes a 100% duty cycle, or total flow when the injector is held fully open, but you should calculate injector size at a lower duty cycle so you won’t run the risk of maxing out your injectors. You can do that by dividing horsepower by duty cycle before solving for the rest of the equations. Let’s assume a safe 85% duty cycle, which results in needing at least 67.6 lb. injectors. You can convert this number from lb/hr to cc/min with this equation:

Injector size in cc/min = Injector size in lbs/hr * 9.71

Injector size = 656 cc/min

To calculate the total fuel flow to find the fuel pump size, calculate for the total fuel requirements by multiplying the injector fuel flow in lb/hr by the number of injectors:

67.6 x 4 = 270.3 lb/hr

Fuel pumps are usually sold in liters per hour of flow so we must convert to lph. Fuel weighs about 6 pounds per gallon. Convert to gallons per hour by dividing by 6, or 270.3/6 = 45 gallons per hour. Convert to liters per hour by multiplying by the conversion rate of 3.785, or 175 liters per hour so the Walbro 190lph would provide just enough fuel for these conditions, however to have some fuel system headspace, just get the 255lph model.